What are the benefits to balancing propellers?

Balancing propellers offers several benefits, including:

1. Reduced Vibration:

Propellers that are out of balance can produce excessive vibration, which can cause damage to the aircraft or other machinery. Vibration is a waste of energy, and can even cause cracks in the airframe, engine parts, and even cause problems with avionics. By balancing the propeller, the vibration can be reduced, leading to smoother operation and a longer service life for the machinery.

2. Improved Performance:

An unbalanced propeller can cause a reduction in performance, including reduced speed, increased fuel consumption, and decreased thrust. Balancing the propeller can help restore optimal performance, resulting in improved efficiency and reduced operating costs.

3. Increased Safety:

An out-of-balance propeller can also create unsafe conditions, such as increased noise and vibration levels, which can lead to operator fatigue and potential accidents. By balancing the propeller, the risk of accidents can be reduced, enhancing the safety of the aircraft or machinery.

4. Longer Service Life:

Balancing the propeller can help reduce wear and tear on the machinery, particularly bearings, which can extend its service life. This can result in lower maintenance costs and higher reliability, improving the overall efficiency of the machinery.

5. Pleasant passenger experience:

Let’s face it, nobody wants to be on a plane that feels as though it is vibrating your body like a lawn mower. This can contribute to motion sickness as well as anxiety for both pilots and passengers alike. A balanced propeller is a contributor to a smooth and enjoyable ride for everyone involved.

Types of Aviation Propeller Unbalance

- Mass force

- Mass moment

- Aerodynamic force

- Aerodynamic moment

Mass force unbalance is when the center of gravity does not lie on the axis of rotation. This is the most commonly considered form of unbalance. Mass moment unbalance is when the minor principal axis of inertia is not parallel to the axis of rotation. This can be an “equal, but opposite” offset of mass. The centrifugal forces may be equal but unbalanced about the axis of rotation.

Aerodynamic force unbalance is when the torque forces on the individual blades are unequal, causing a resultant force to exist. This is similar to the resultant force in mass force unbalance. Aerodynamic moment unbalance is when the thrust forces on the individual blades about the center of rotation are unequal. This causes a similar moment similar to the mass moment unbalance.

For marine propellers, unbalance (in addition to propeller damage or deformation) can cause excess cavitation. Cavitation is when the water vaporizes along the back side of the propeller blades due to high pressure. This cavitation effect increases with the increase in rotational speed. Excessive cavitation can cause physical damage to the propeller’s surfaces as the bubbles on the blade collapse. This can cause erosion, pitting on the surface, excess vibration, reduced bite and reduced overall efficiency. In extreme cases, it can even cause blades themselves to tear off due to fatigue failure.

In many cases, most small boat propellers are designed without cavitation resistance in consideration and this accounts for an increased need in propeller maintenance. A properly balanced boat propeller can reduce the potential damage and wear, thereby reducing the cost of maintenance, let alone replacement.

Overall, balancing propellers is an essential maintenance task that can help improve the performance, safety, and reliability of aircraft and other machinery. In the case of high-performance boats, all of these effects and benefits are amplified exponentially.

It is recommended to have the propellers balanced periodically to ensure optimal performance and prevent potential problems.

How are marine propellers balanced?

Marine propellers can be balanced using various methods, depending on the type of propeller and the balancing equipment available. The most common methods used for marine propeller balancing include:

Static Balancing:

This method involves placing the propeller horizontally on a set of support blocks and checking the blade’s weight distribution. The heaviest blade will rotate to the bottom, at which point the blade’s heavier side is identified and then trimmed or drilled to remove the excess weight until the propeller is balanced.

Dynamic Balancing:

This method involves mounting the propeller onto a dynamic balancing machine and rotating it at high speed while measuring its vibration levels. That data is then used to by the software to identify the location of the blade’s heavy spots, and the correction weights can be added to or removed from the propeller to achieve a balanced state.

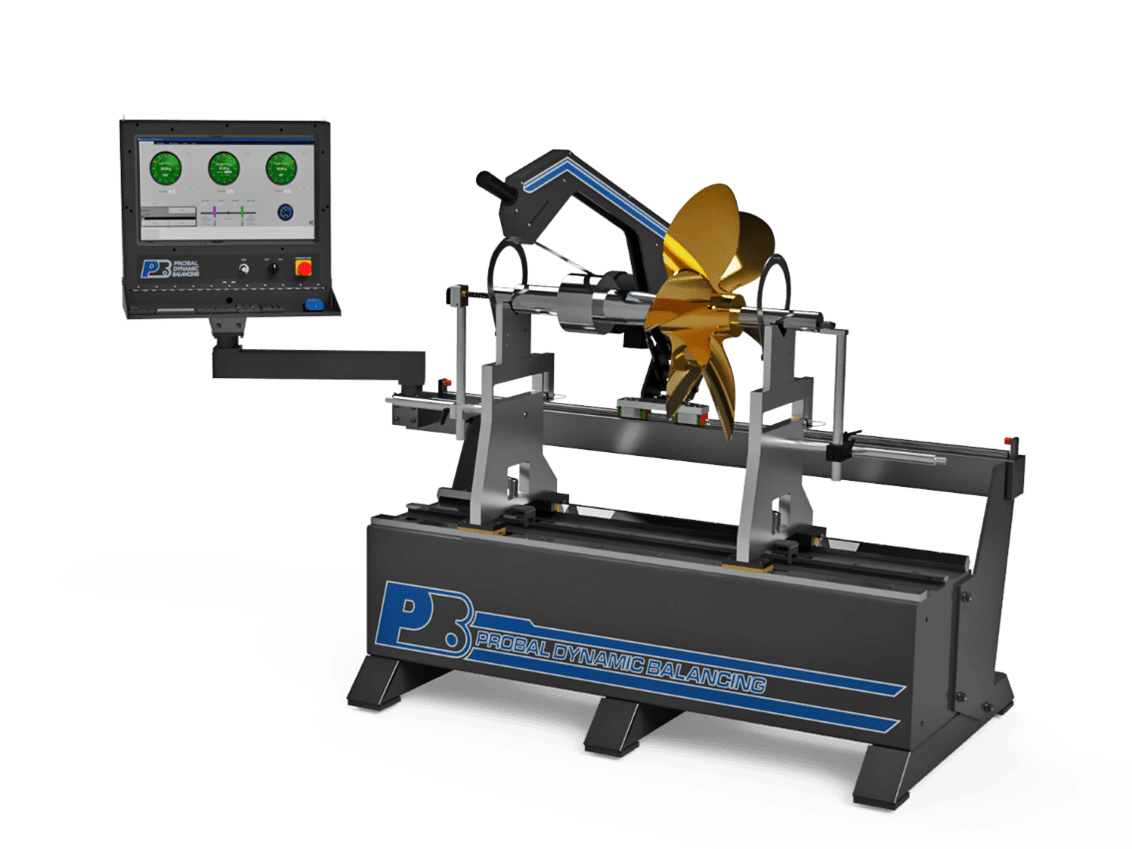

The most common Probal Dynamic Balancing machine for propellers is one of our horizontal balancing machines. We have a range of models to accommodate parts of varying sizes and weights. With propellers, the greater diameter of the part can vary quite a bit depending on the application.

Marine propellers can also be balanced on the vessel, using portable balancing equipment. However, this method requires skilled personnel and can be time-consuming.

Dynamic balancing of marine propellers typically involves the following steps:

Preparation:

The propeller is thoroughly cleaned and inspected to ensure that it is free of debris and any damage that may affect the balancing process. The propeller is then placed on the balancing machine, which is designed to support the propeller securely. Depending on the balancing machine’s drive system this can be done multiple ways.

Probal Dynamic Balancing machines offer three effective drive methods:

- In-line End Drive: This method involves having the drive shaft directly in line with the propeller’s axis of rotation. The part is generally affixed to a driveshaft and adapter, which is then connected to the motor and gearbox. This is particularly useful for larger parts or parts that lack an open area for a belt drive to maintain consistent contact with the part surface.

- Overhead Drive: This method utilizes a drive belt contained within an arm overtop the part. The Probal overhead drive can be held down onto the part to engage rotation. This drive system uses spring return to lift it back out of the way when not in use, disengaging the drive by simply lifting up or letting go of the handle. It is mounted to its own linear bearing rail behind the part, giving you the ability to traverse from side to side as needed.

The overhead drive system also allows for the fastest loading and unloading time, as there is nothing affixed to the part and no belt wrapped around the part itself. Simply remove it from the bearings and place the next part on the machine. - Wrap-Around Drive: The third method offered utilizes drive motor system below the part to turn a belt which is wrapped around the part itself. This method also offers an added layer of safety, as the belt is holding the part onto the bearings. The belt tension is loosened and tightened before and after balancing by turning a handle on the front of the drive system. The Probal wrap-around drive is also on linear bearings, but unlike the overhead drive which has it’s own rail behind the columns it rides on the same rails as the columns themselves.

Spin up:

The propeller is rotated at high speed, typically between 500 and 3000 revolutions per minute (RPM), using an electric motor. The balancing machine is designed to keep the propeller stable during the spinning process, ensuring that it rotates smoothly.

Vibration measurement:

During the spinning process, the machine measures the propeller’s vibration levels using sensors attached to the balancing machine. The vibration data is collected and analyzed by our specialized Probal software, which identifies the heavy spots or unbalanced areas of the propeller.

Correction:

The unbalanced areas of the propeller are corrected by adding or removing small amounts of material using welding or grinding techniques. The correction process is repeated until the propeller is balanced within the required tolerance level. Our proprietary software will tell the operator where material needs to be removed, as well as how much, to bring the center of mass back in line with the center of rotation.

Final testing:

Once the balancing process is complete, the propeller is retested to ensure that it meets the required vibration levels or unbalance tolerance. The final test typically involves measuring the propeller’s vibration levels using the same sensors used during the initial test.

Reporting:

A report is generated detailing the balancing process and results, which is typically provided to the vessel owner or operator for their records.

Overall, dynamic balancing of marine propellers is a highly specialized process that requires specialized equipment, skilled personnel, and attention to detail. Properly balanced marine propellers can reduce vibration, improve fuel efficiency, extend the service life of the vessel’s components, and enhance safety.

For more information on our line of dynamic balancing machines see our product line at probaldynamicbalancing.com or contact us at sales@probaldynamicbalancing.com.

We have a range of machines displayed on our website on the Products tab and we are able to customize to accommodate solutions for most parts.