Our experience and long history of working with dynamic balancing systems and numerous applications allows us the unique advantage of being able to provide customized solutions for our customers. We work with you from the beginning to understand your specific balancing needs and manufacturing challenges to provide the most comprehensive balancing machine solutions available. Our application engineers are ready and waiting to help get you off the ground with your new machine in the least amount of time possible.

Request a quote now and a dynamic balancing specialist will work with you personally.

Request a quote now and a dynamic balancing specialist will work with you personally.

Overview

Dynamic balancing machines are capable of balancing the widest range of parts. Our hard-bearing dynamic balancing machines use piezo-electric sensors to read unbalance in real time. They are capable of fast (approximately 3-second) sample times, so you can get multiple readings in a fraction of the usual time. Live encoder feedback clearly displays the rpm and the correction location while rotating the part by hand. Our dynamic balancing machines use multi-speed permanent calibration with an included proving rotor, making it unnecessary to re-calibrate or use test weights when changing parts. Simply choose the speed you need to run, spin up the part, and start collecting data.

OUR LINEUP

ProBal's horizontal balancing machines offer optimized balancing solutions for diverse component weights and industries.

MACHINES FOR ALL TYPES OF PARTS

Let us help you choose the right balancing machine.

Special Features

- Composite-filled steel bases for extra stability

- Linear bearing rail system for columns

- Variety of trunnion types to suit any part

- V-blocks

- Roller bearings

- Pillow blocks

- Modular design, allowing length extension

- 3 different drive types

- Overhead drive

- Wrap-around drive

- Direct drive

- Customized balancing solution specifically tailored to your part

- Simple to use touchscreen friendly balancing software

- Multiple Computer Solutions

- Swinging Arm

- Rolling Console

- Simple Laptop (Low Cost)

- First class training and service

Applications

- Electric Motors

- Rotors

- Crankshafts

- Driveshafts

- Flywheels

- Turbochargers

- Centrifugal Fans

- Pumps

- Impellers

- Spindles

- Grain Augers

- Agricultural Parts

- Straw Choppers

- Grain Grinders

- Paper Mill Rollers

- Mud Pumps

- Cable Reels

- Propellers

Multiple Drive Options

ProBal offers three different variable speed drive solutions, providing the best versatility in its class. Our exclusive overhead drive eliminates the need for fumbling with different length belts and allows you to drive from virtually any surface on the part. Our traditional wrap-around belt drive is a new evolution of an old standard, allowing for greater variation of part size without needing as many belt lengths. We also offer our direct-drive in-line motor system for larger parts that don't have a simple area for a belt to grip onto.

Various Control Choices to Fit Different Needs

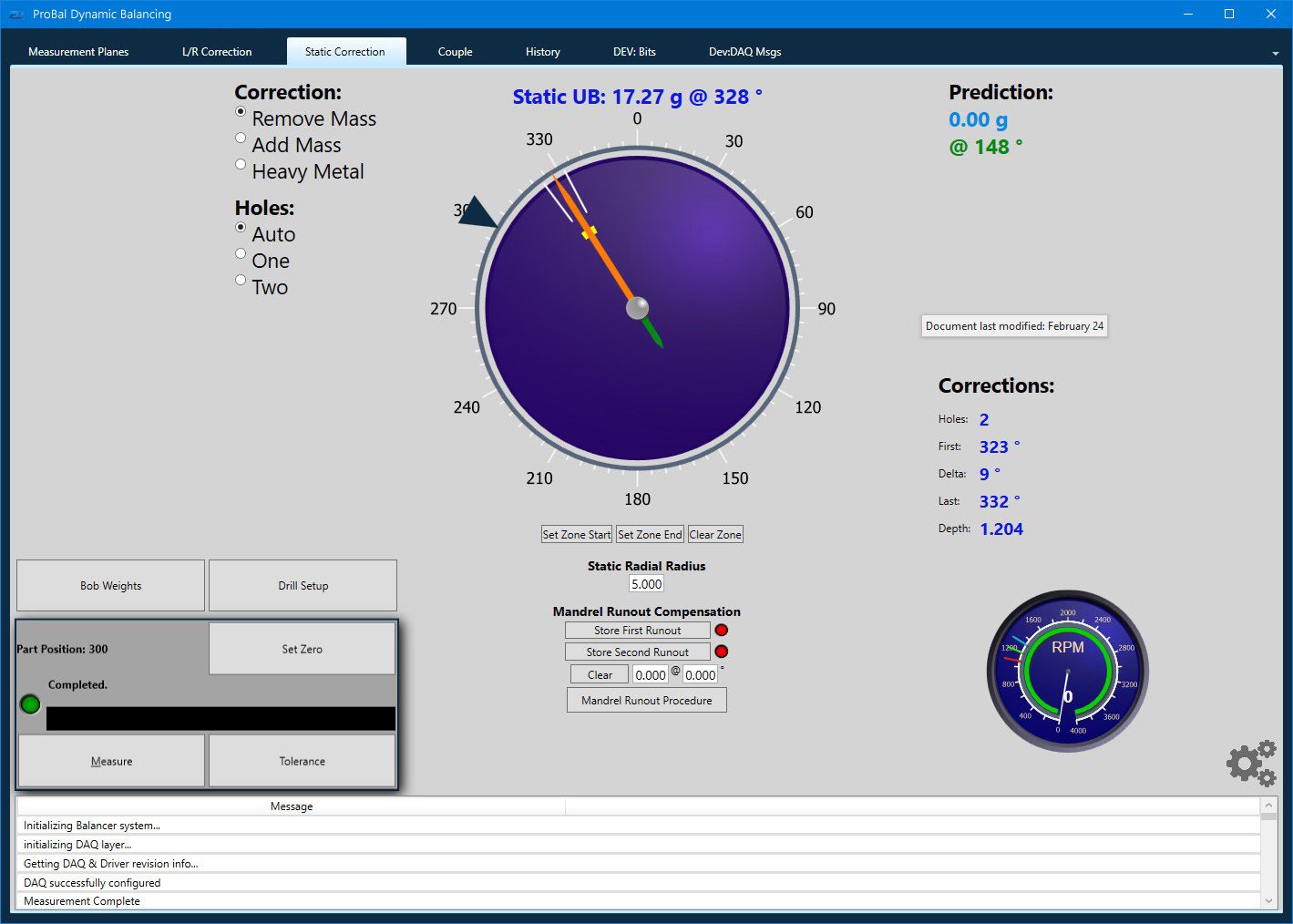

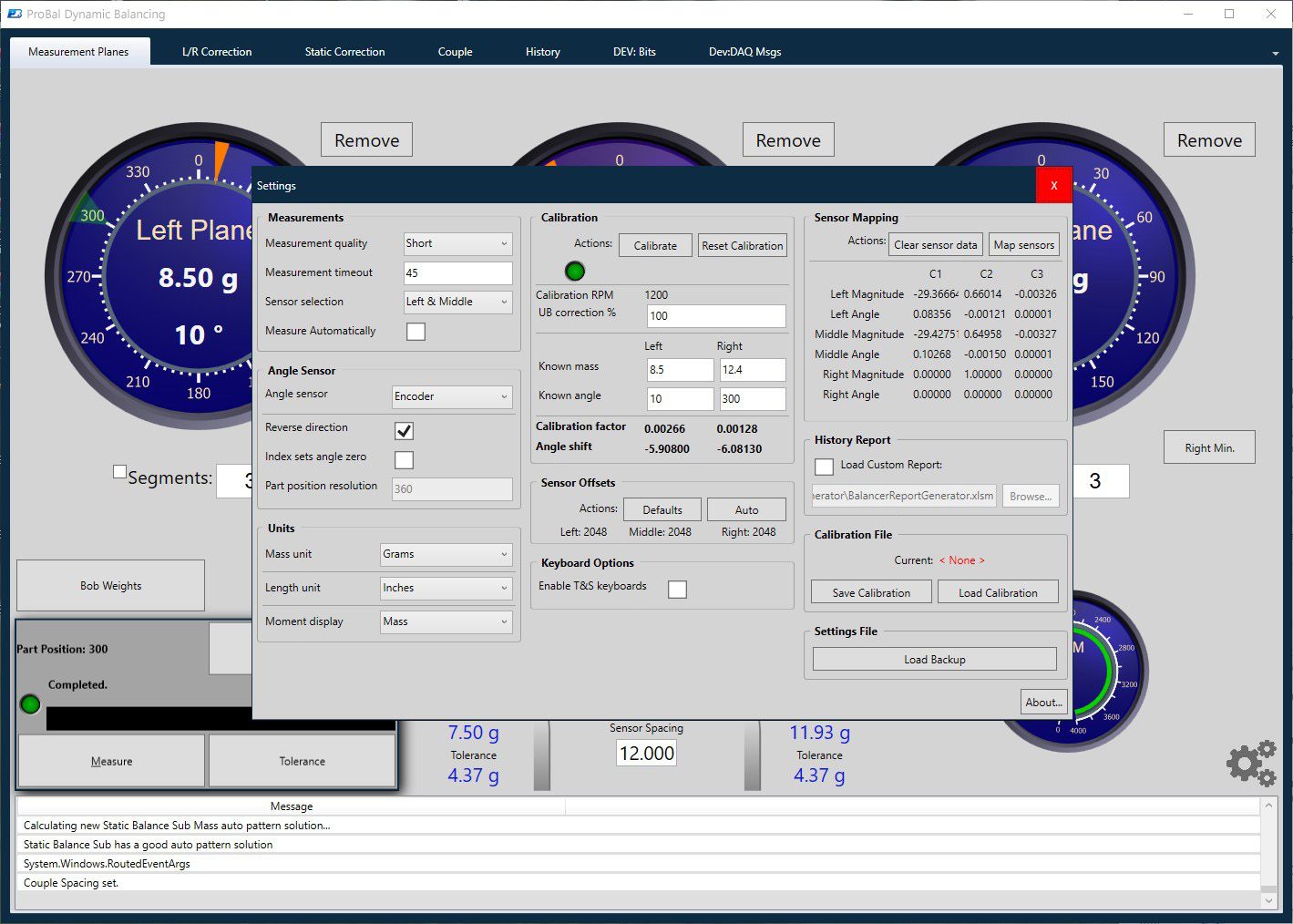

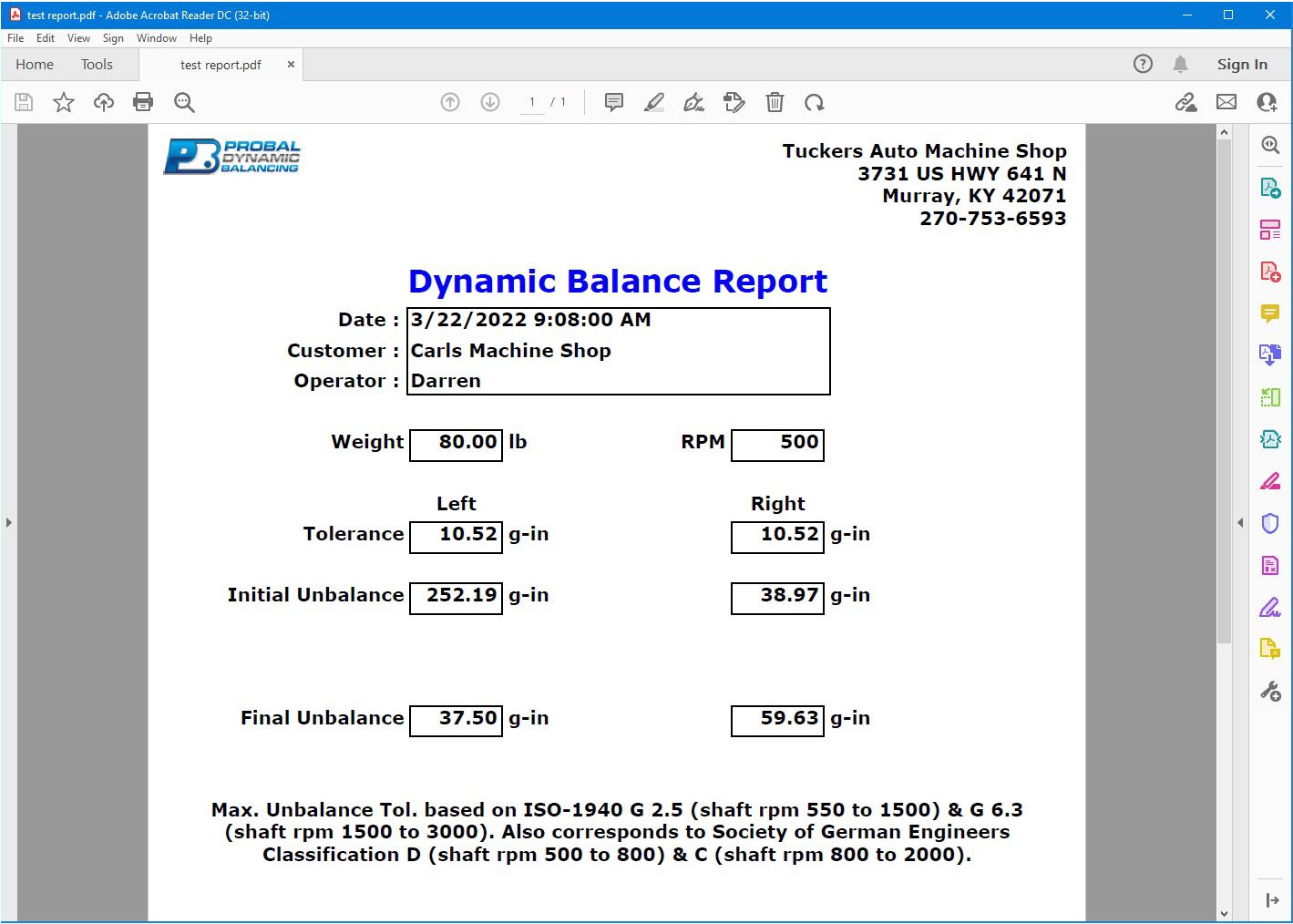

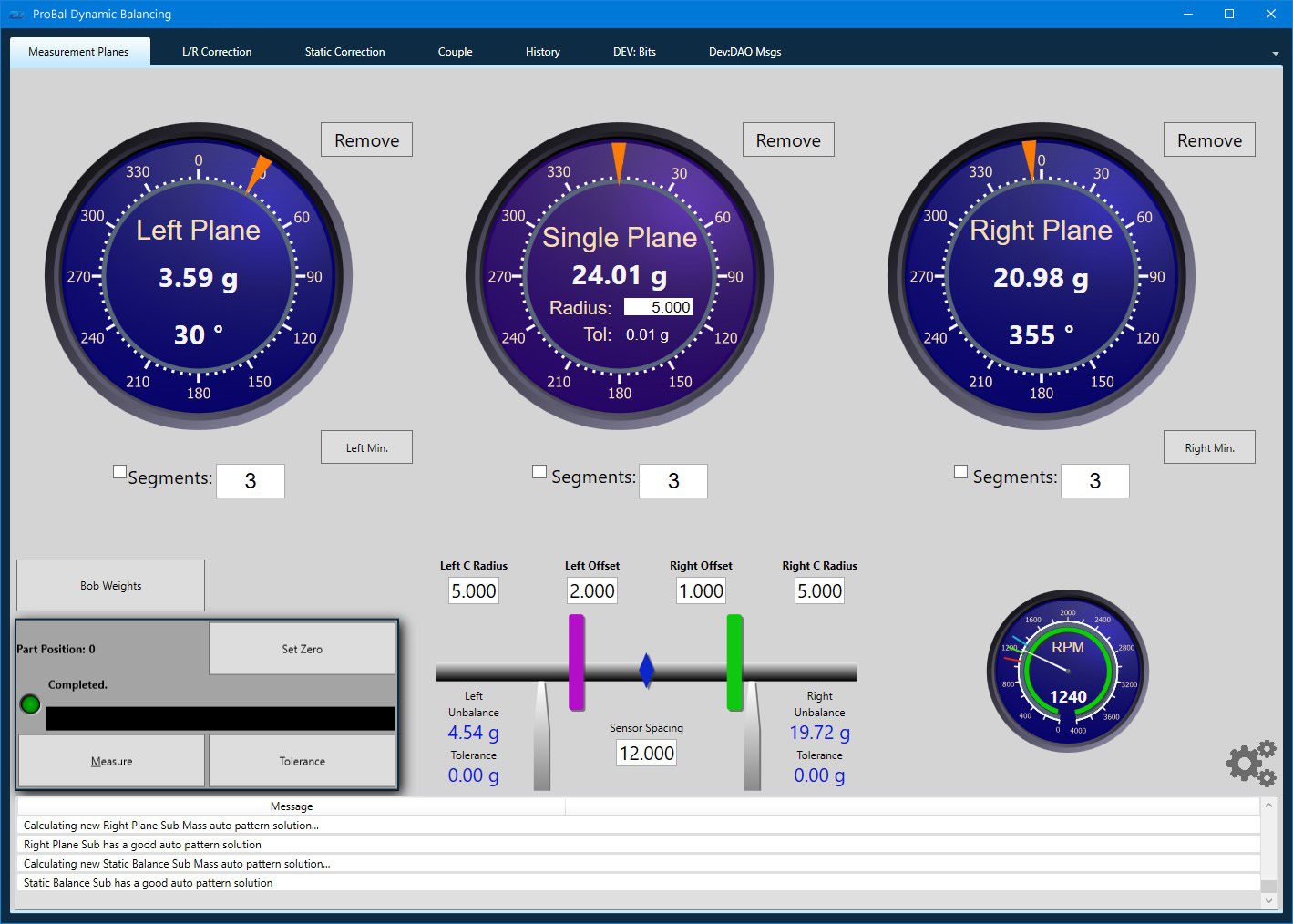

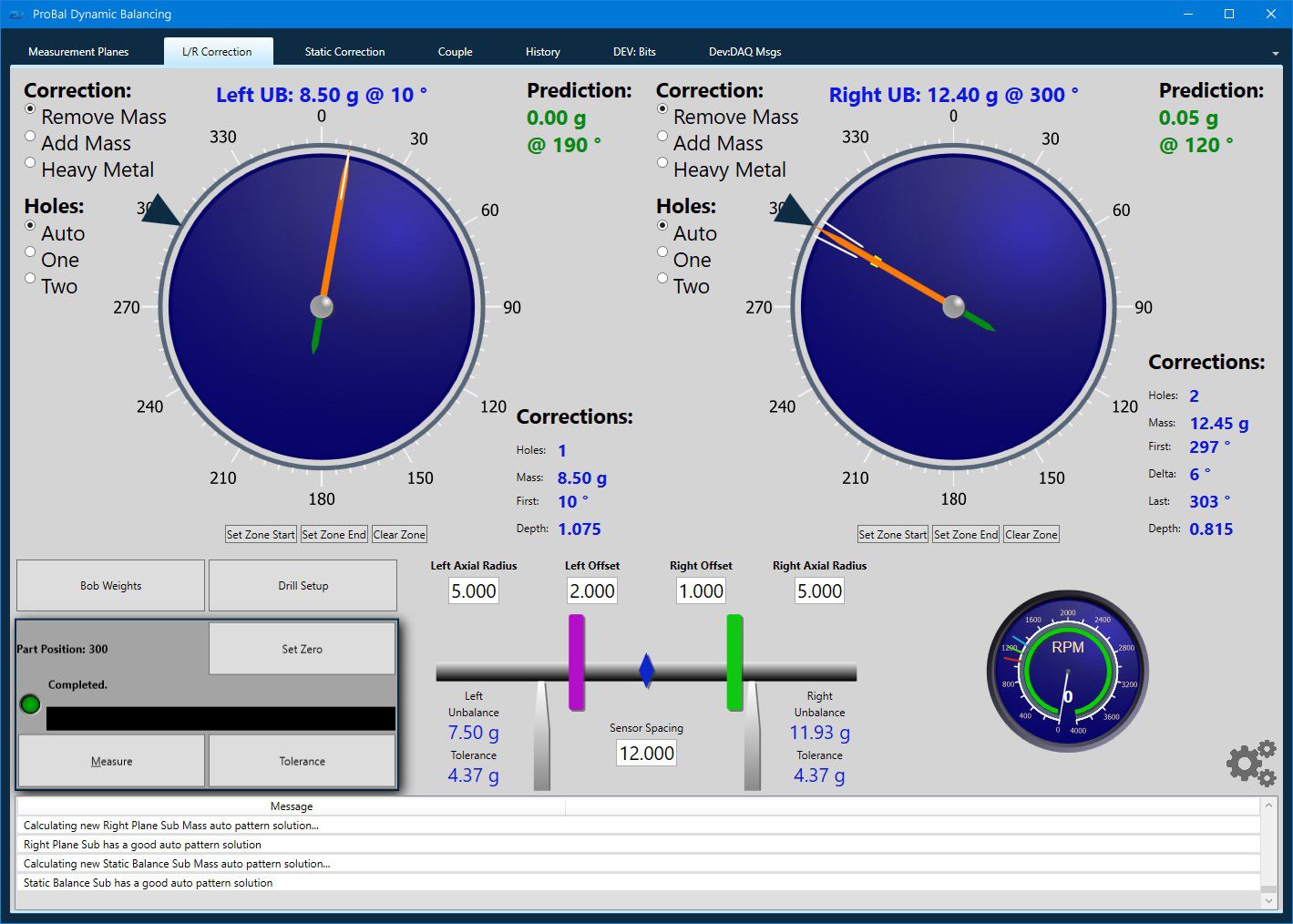

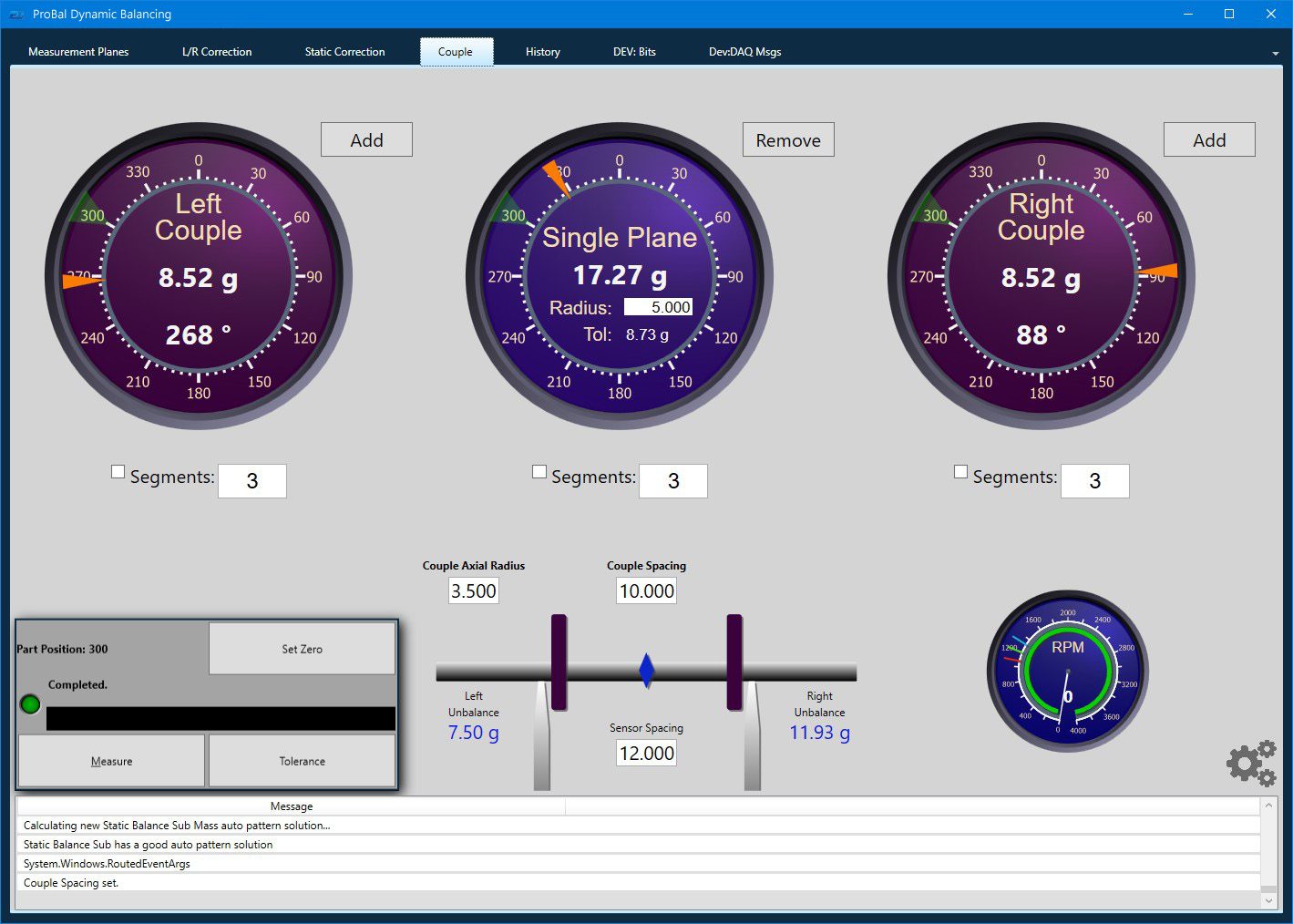

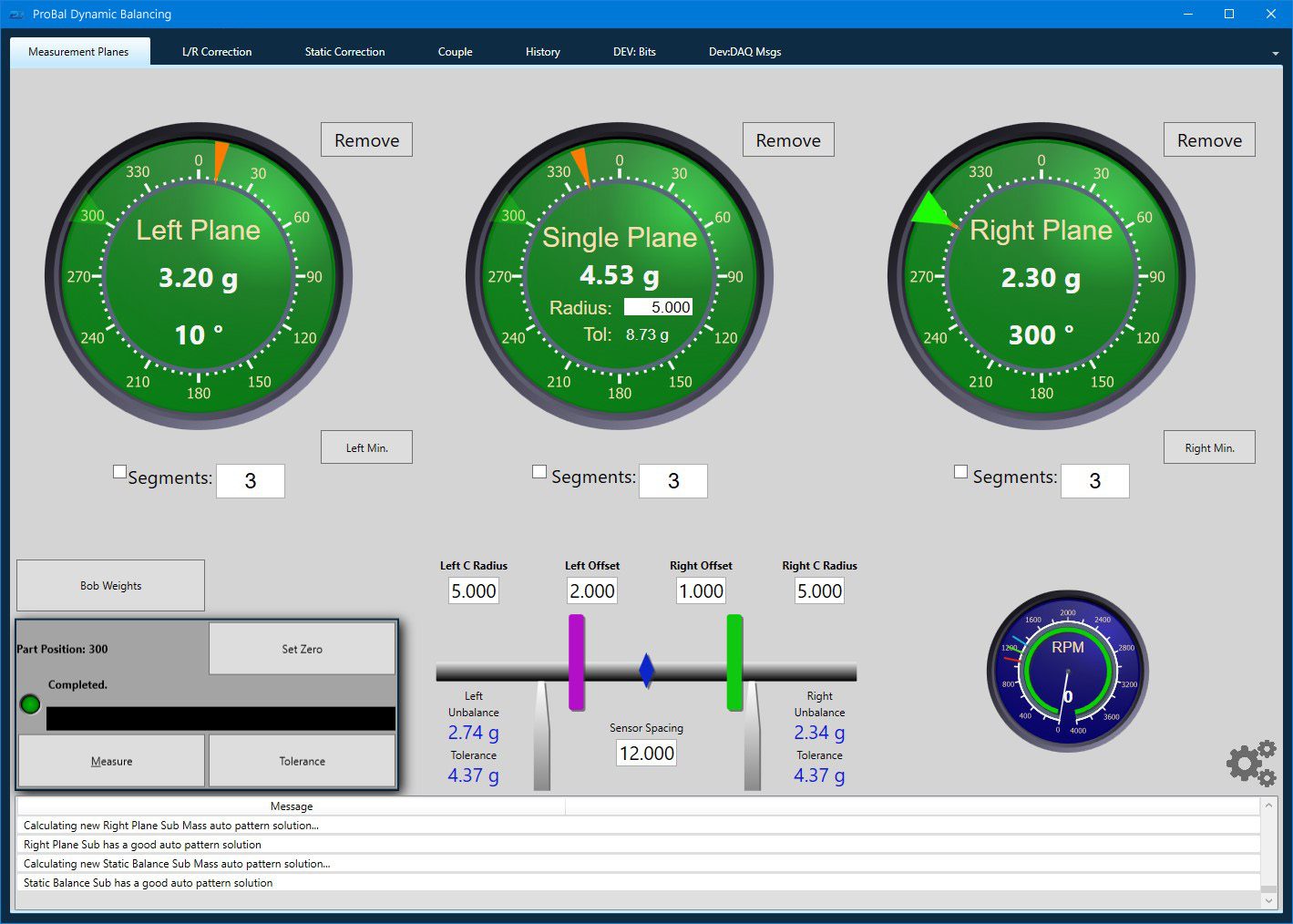

Multiple control panel solutions are available including a full height rolling console, swing-arm operator panel, or simple laptop for those with low-cost requirements. The ProBal Dynamic Balancing control system is fast and efficient. We have a simple, modern, and highly sophisticated instrument designed to quickly measure dynamic un-balance on parts ranging from just a few pounds to rotating assemblies weighing tens of thousands of pounds. We utilize advanced analog filtering and the latest digital signal processing techniques to provide very fast and accurate measurements displayed in an intuitive user interface.

Industry Leading Technology

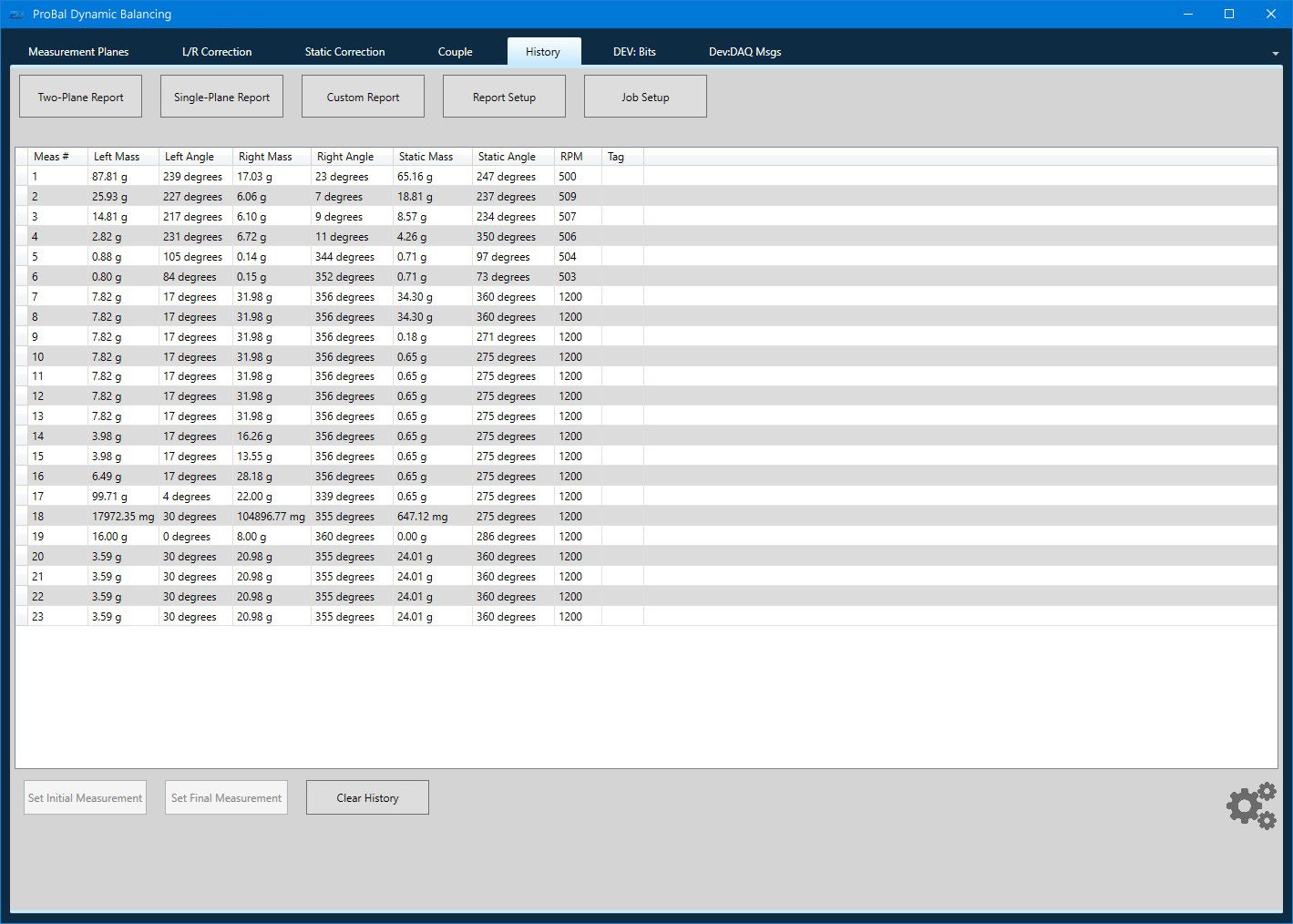

On the Home screen you’ll find everything you need to quickly understand the dynamic condition of the part being balanced and you can easily apply offsets and compensations to fine tune your correction strategy. Tools for calculating your balancing tolerance to industry standards are built directly into the software including options such as key compensation, tooling compensation, segmentation, drill correction, measurement history, and balancing reports.