ProBal Dynamic Balancing works closely with the end-user to supply vertical balancing machines specifically suited to the part to be balanced. While it is acceptable many times to build a universal vertical balancer it is more common to build a machine with a customized spindle to directly accept the rotating assembly or part.

Contact us today to discuss the ultimate design to balance your part most efficiently.

Contact us today to discuss the ultimate design to balance your part most efficiently.

Vertical Balancing Machine Features

- Multiple Measurement Modes

- -Single Plane

- -Dual Plane

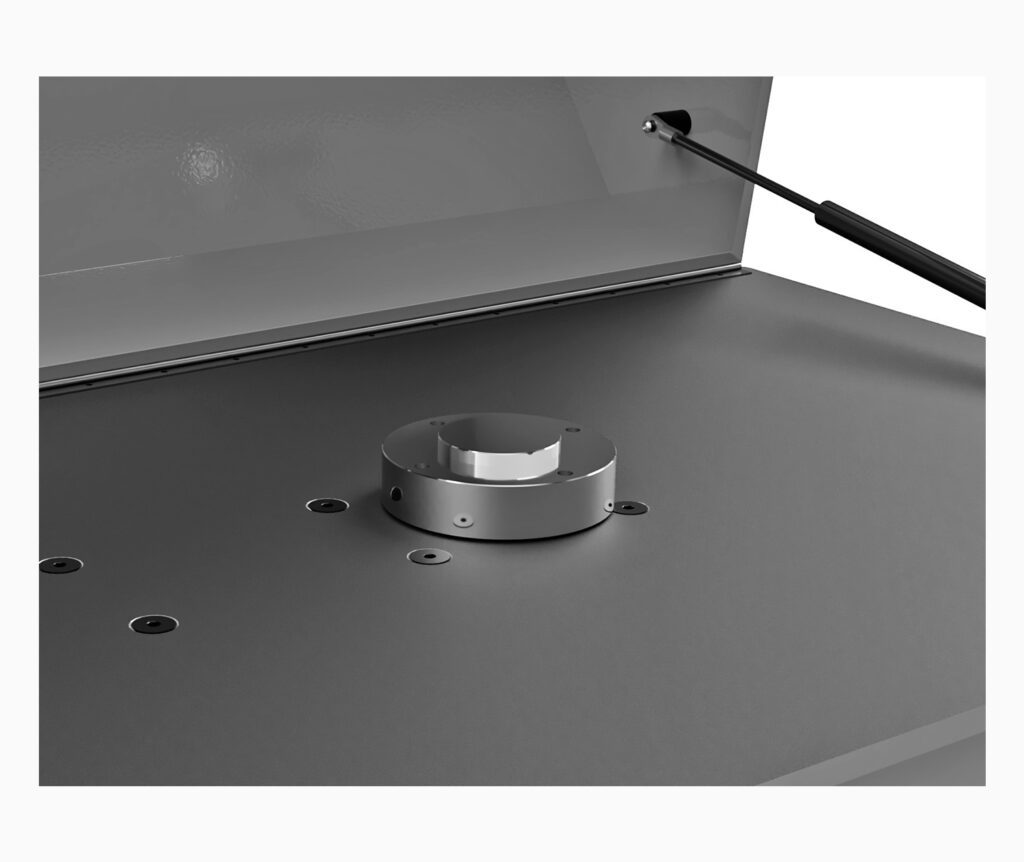

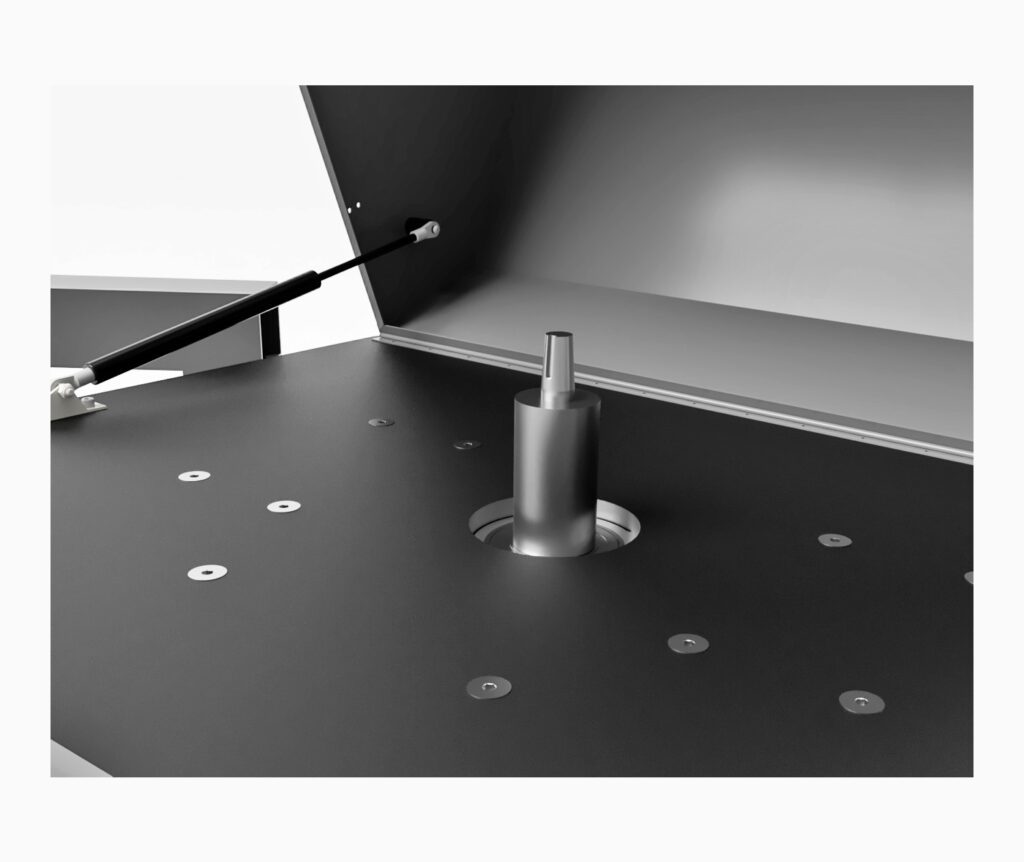

- Custom Spindle Design

- Drill Press Integration

- Fast Measurement Cycles

- Windows 10 Embedded

- 22” Touchscreen Computer

- Various Automation Solutions

Overview

Our vertical balancing machines are the perfect choice for balancing disk-like parts that don’t have their own arbor. Vertical balancers are a faster means of getting high-definition single or dual plane data. Our vertical series still use our fast-reading sensors and the same state of the art software and electronics as our universal machines.

ProBal vertical balancing machines are great for parts like: flywheels, pulleys, gears, fans, and clutch plates. We also offer the ability to customize to meet our customers needs, including safety protection.

ProBal vertical balancing machines are great for parts like: flywheels, pulleys, gears, fans, and clutch plates. We also offer the ability to customize to meet our customers needs, including safety protection.

Application Support

Typical mounting solutions for a component mounted with a vertical axis can include a hub with a multi-bolt hole pattern, tapered bore or shaft, collet, or clamping chuck. Universal and part-matched mounting solutions are both available. We can supply a custom spindle shaft or provide design constraints and guidelines so that our customers have control of their own processes.