DYNAMIC BALANCING MACHINES

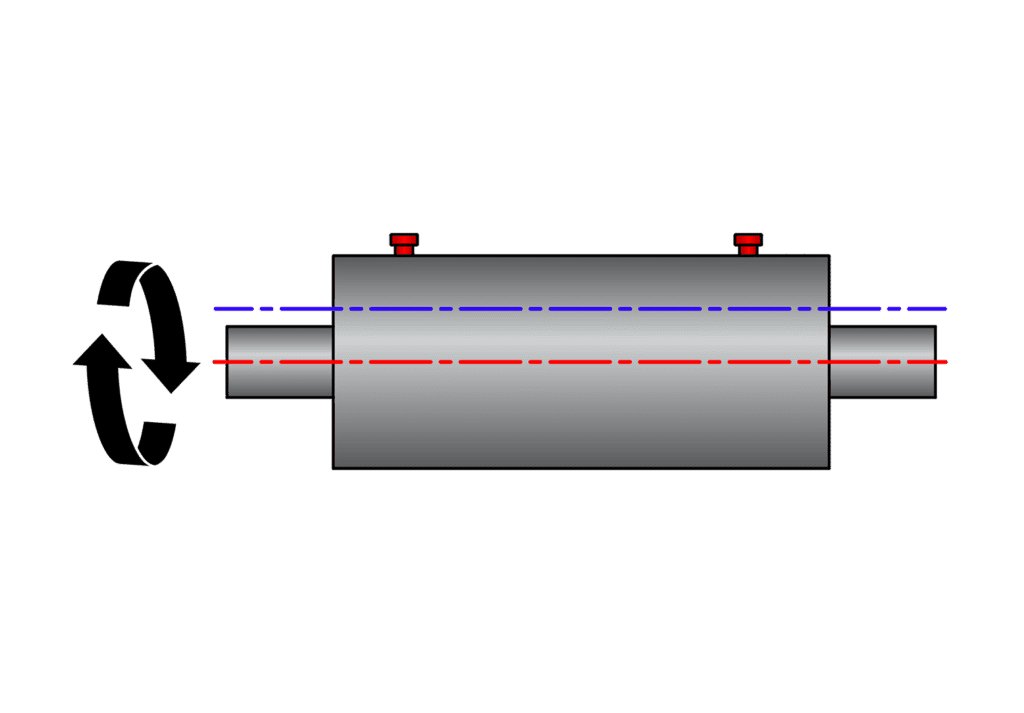

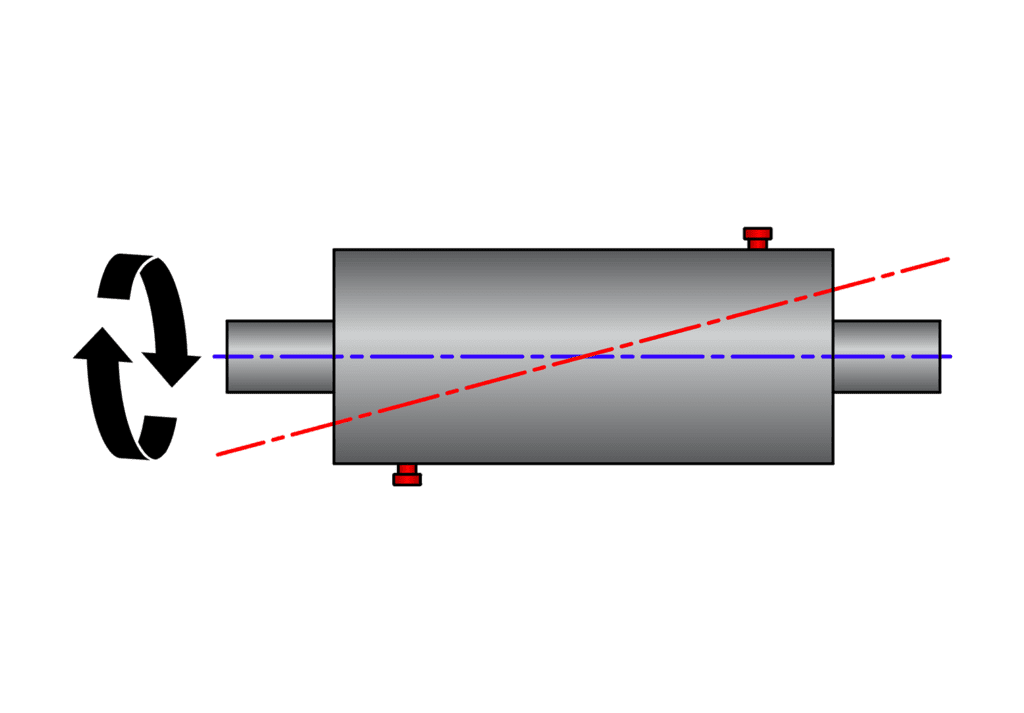

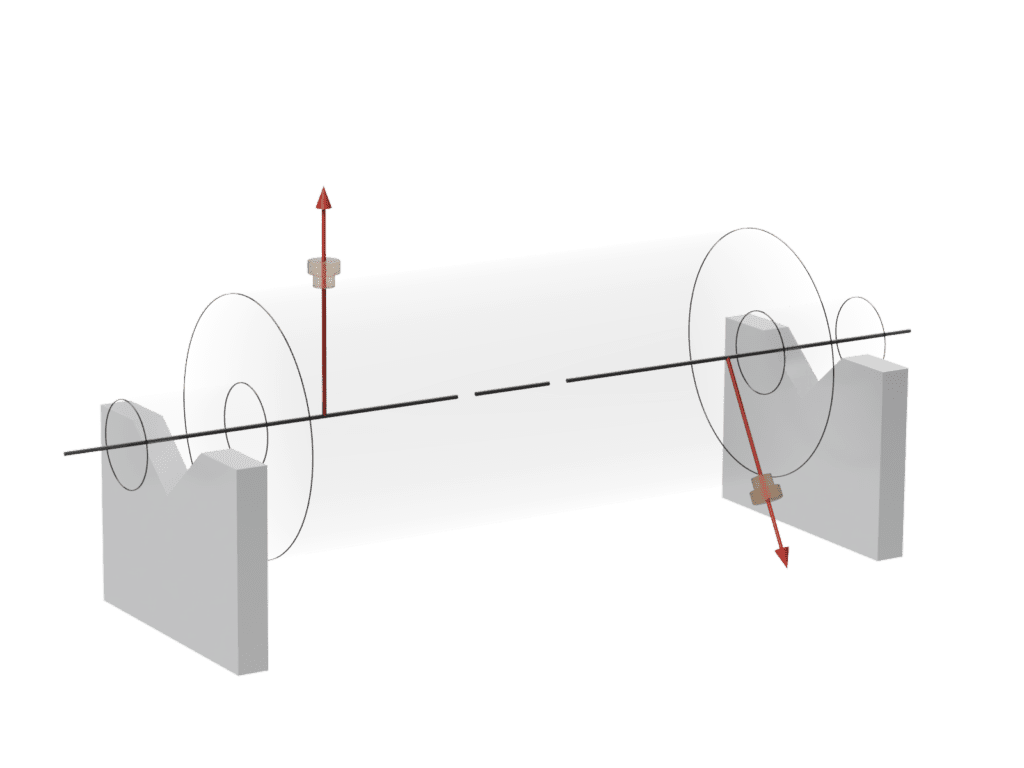

Dynamic balancing is a process which brings the center of mass of a rotating part back in line with its center of rotation. This is done by rotating the part on the dynamic balancing machine at speed and measuring the vibration caused by the eccentric mass. The operator then either adds or removes material to bring the center of mass back into alignment, within acceptable tolerances.

What are the different types of balancers?

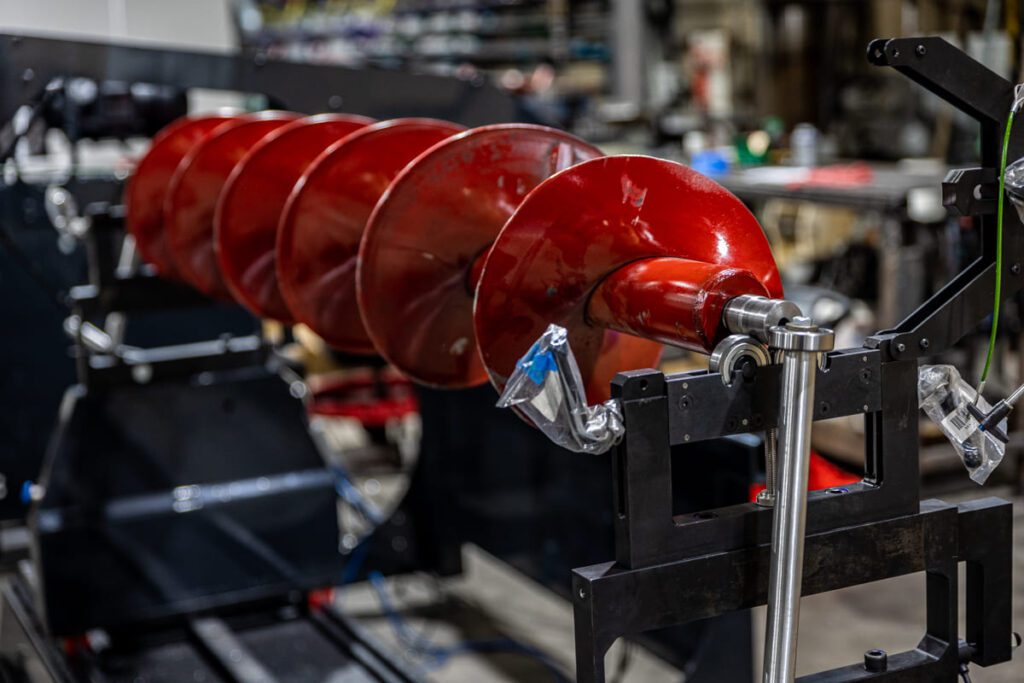

Probal Dynamic Balancing Machines offers machines tailored to several industries, but all of them can be placed into one of two primary categories – horizontal or vertical machines. For the majority of parts, horizontal balancing machines are the proper orientation to accommodate the widest range of sizes and shapes. Any parts with substantial lengths, such as driveshafts and agricultural augers, would naturally need to be balanced on a horizontal machine where the modular base system can be extended to reach as far as needed.

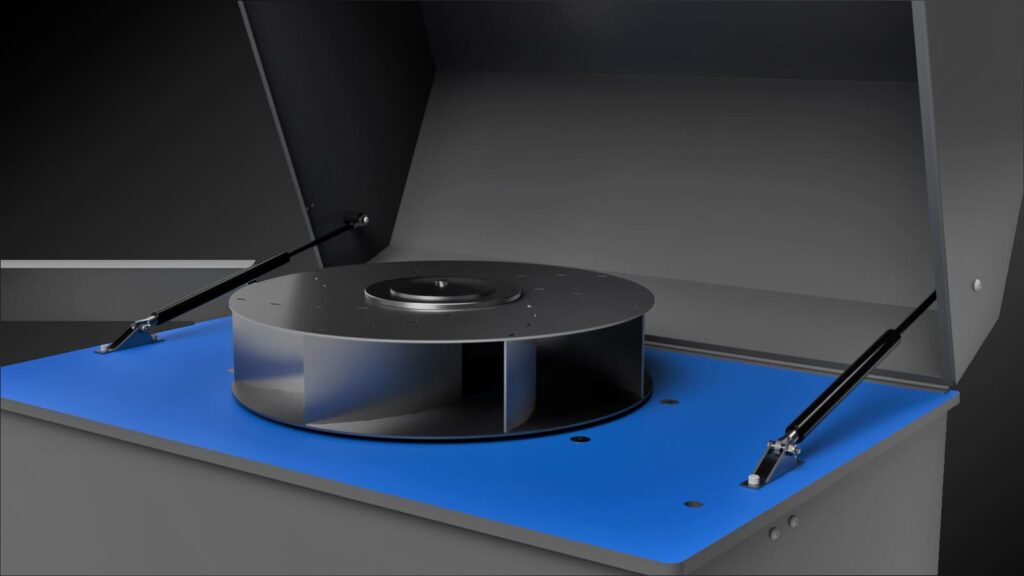

Vertical balancing machines consist of a rigid tabletop-style base with the drive components contained within the base. The part is mounted to a flange system above the top surface, which then rotates the part along a vertical axis of rotation. Vertical balancing machines are often ideal for smaller or narrower parts with no cylindric surfaces in which to ride on the bearings of a horizontal machine.

Vertical balancing machines consist of a rigid tabletop-style base with the drive components contained within the base. The part is mounted to a flange system above the top surface, which then rotates the part along a vertical axis of rotation. Vertical balancing machines are often ideal for smaller or narrower parts with no cylindric surfaces in which to ride on the bearings of a horizontal machine.

Which is right for your application?

Application Support

At ProBal Dynamic Balancing, we pride ourselves on providing industry-leading horizontal balancing machines designed for a wide range of applications. Our versatile solutions cater to an extensive list of industries and components, including pump impellers, props, augers, fans, electric motors, rollers, crankshafts, and driveshafts. Our innovative technology ensures high-precision balancing for all these applications, delivering optimal performance and long-lasting durability.

Our engineers at ProBal Dynamic Balancing have meticulously crafted our horizontal machines to address the unique needs of each application. We understand that different industries have distinct requirements, and our adaptable machines can be customized accordingly. With user-friendly interfaces, efficient calibration processes, and top-notch accuracy, our horizontal balancing machines help businesses across various sectors enhance their productivity and achieve unparalleled levels of quality. Experience the difference with ProBal Dynamic Balancing and discover the perfect solution for all your balancing needs.

Our engineers at ProBal Dynamic Balancing have meticulously crafted our horizontal machines to address the unique needs of each application. We understand that different industries have distinct requirements, and our adaptable machines can be customized accordingly. With user-friendly interfaces, efficient calibration processes, and top-notch accuracy, our horizontal balancing machines help businesses across various sectors enhance their productivity and achieve unparalleled levels of quality. Experience the difference with ProBal Dynamic Balancing and discover the perfect solution for all your balancing needs.

Multiple Drive Options for Enhanced Flexibility

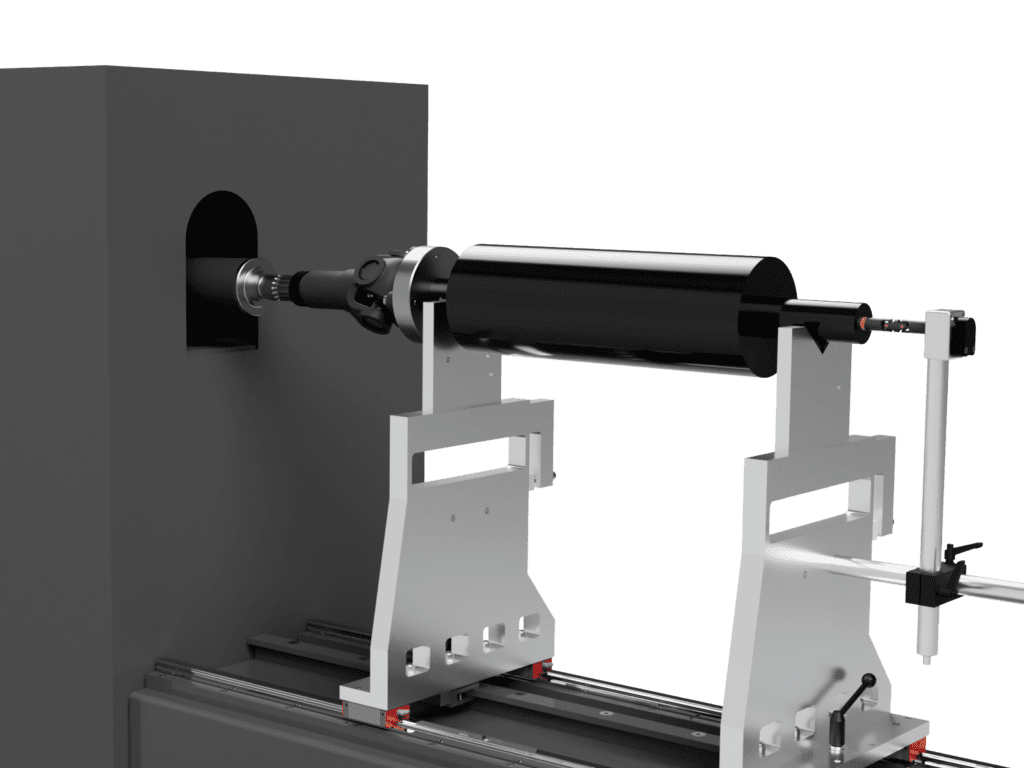

End Drives are particularly well-suited for large parts that require mounting to a flange. In this configuration, a part is secured to a custom flange at the end of a driveshaft and powered by a high-torque gear system within the cabinet. This drive system is exclusively compatible with parts that have in-line mounting.

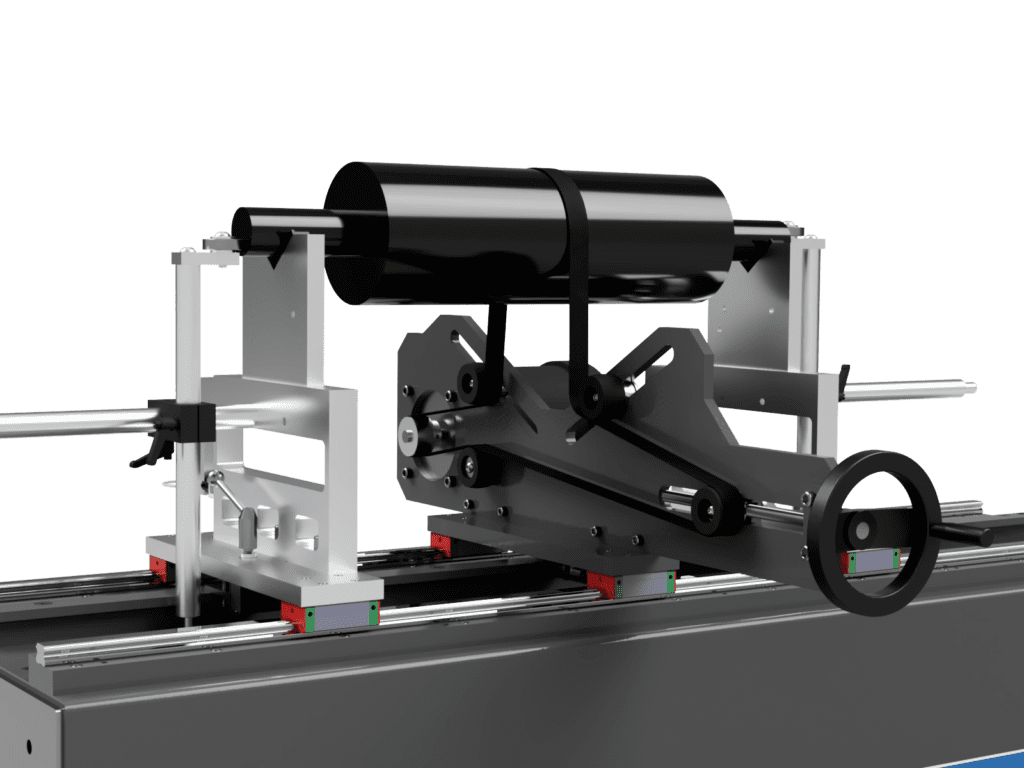

Wrap-around Drives are positioned between the columns on the machine's base and rotate the part using a belt wrapped around it. Although these drives are more cumbersome to set up than overhead drives, they offer increased effective torque due to greater contact between the belt and the part.

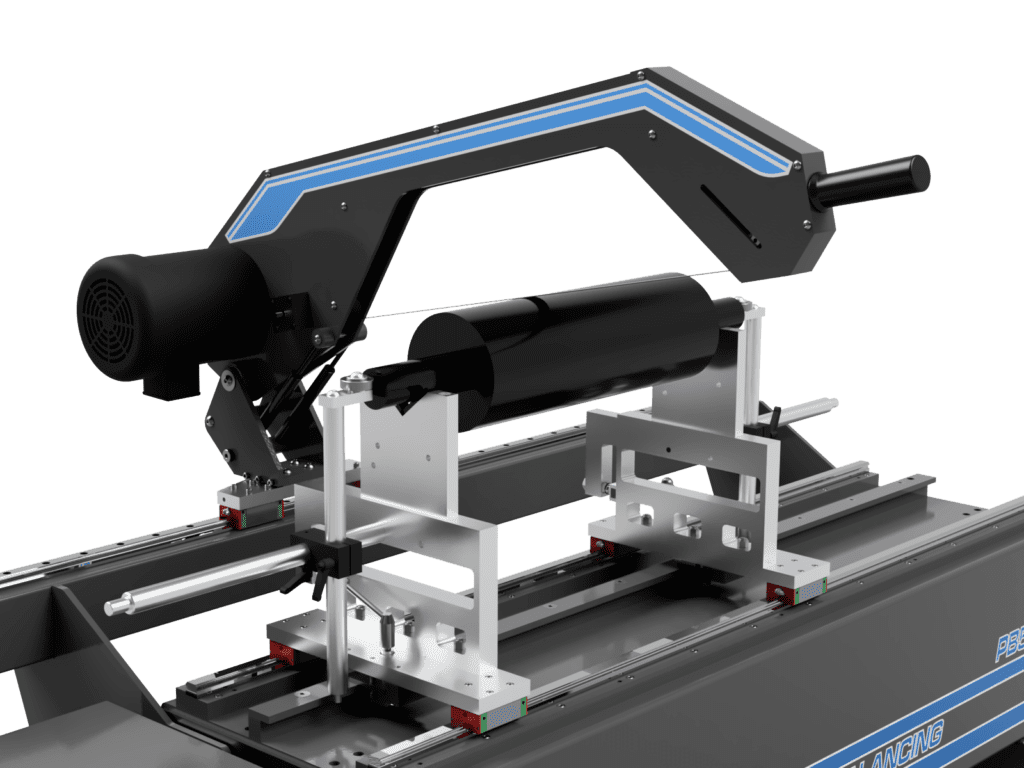

Our innovative Overhead Drive is by far the most efficient and user-friendly option, significantly reducing setup time for any suitable application. Mounted on a linear rail at the rear of the machine, it can be effortlessly moved from one location to another, making it particularly effective for machines designed to handle a wide variety of parts. The overhead drive operates by lowering onto the part and rotating it with a belt system, similar to the wrap-around drive. There is no need for fixturing or belt adjustments during the balancing process, resulting in considerable time savings. To begin, simply place the part on the columns and lower the drive. Once completed, release the drive, which will automatically retract and move away from the part. Our overhead drive's speed and convenience make it the optimal choice for reducing setup time.

Highly Customizable

ProBal Dynamic Balancing leads the industry with its highly customizable balancing machines, catering to a diverse range of applications and industries. One of the most frequently required features is the ability to extend the length of a machine, enabling the balancing of long parts without requiring a specialized model. In addition, ProBal's machines can be equipped with extended height columns to support large diameter components. Furthermore, ProBal Dynamic Balancing machines can be modified to accommodate parts across a wide range of weight capacities, making them suitable for a multitude of applications. The option to add a third column provides support for complex parts. Multiple drive options can even be integrated into a single machine, allowing users to seamlessly switch between different parts and processes. With such a high level of customization, ProBal's balancing machines have become the go-to solution for businesses seeking optimal performance and efficiency in their operations.

Vertical dynamic balancing machines can have certain advantages over horizontal machines depending on the situation. For instance, they typically require less floor space, which is particularly beneficial in workshops or manufacturing facilities where floor space is at a premium. They're also well-suited to balancing disc-shaped or flat rotors like flywheels, clutch plates, and brake discs. These rotors can be mounted vertically without needing additional support, leading to more accurate and efficient balancing.

Both vertical and horizontal machines can be effectively integrated into automated systems, depending on the requirements and constraints of the application. That said, vertical machines can have some advantages in semi and fully automated balancing processes. They can also make automated loading and unloading of parts easier. Robotic arms or other material handling systems can often grip and position rotors more easily in a vertical orientation.

Vertical machines can sometimes integrate more seamlessly with correction methods, such as drilling or milling stations, leading to a more streamlined overall process. However, whether to use vertical or horizontal machines in a semi or fully automated setting is not a one-size-fits-all decision. It depends on a variety of factors including the type and shape of the rotor, production volume, available space, and specific balancing requirements. It's important to conduct a thorough analysis of the application requirements to determine the most suitable machine type for a vertical balancing process.

Our vertical balancing machines accommodate single and dual plane parts, can be fitted with a drill press or welding arm for corrections or safety enclosures if required, and include a custom spindle design for your part or assembly. Our vertical machines use the same modern, fast, user-friendly software and hard-bearing spring designs that make our universal balancing machines so accurate and efficient. We will work closely with you to design and deliver the machine that best suits your needs.

GET IN TOUCH

Do you have a question you would like to ask us?

CONTACT

- PROBAL DYNAMIC BALANCING

- 14 Whitleys Ridge Lane

- Gainesville, TX 76240

- Sales@probaldynamicbalancing.com

- (940)-668-1126

- (940)-668-8006

- (650)910-7240