AUGER BALANCING INTRODUCTION

ProBal auger balancing machines are specifically designed to ensure that augers, which are helical tools used for moving material or drilling, operate with optimal efficiency, minimal vibration, and extended lifespan. An unbalanced auger can lead to operational inefficiencies, wear and tear on equipment, and even pose safety risks.

We stand as an industry leader in crafting auger balancing machines, leveraging our vast experience in dynamic balancing and innovative technology. Our deep understanding of augers combined with a commitment to quality, customization, and competitive pricing showcases our unparalleled expertise and holistic approach to auger balancing solutions.

We stand as an industry leader in crafting auger balancing machines, leveraging our vast experience in dynamic balancing and innovative technology. Our deep understanding of augers combined with a commitment to quality, customization, and competitive pricing showcases our unparalleled expertise and holistic approach to auger balancing solutions.

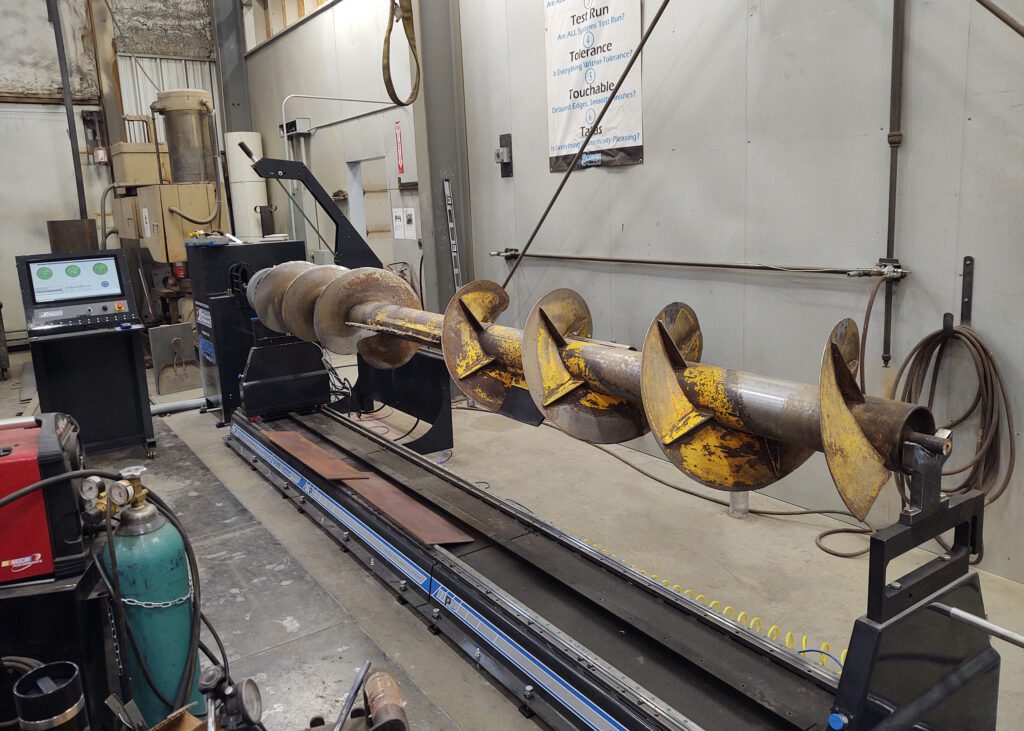

AUGER BALANCING MACHINE PACKAGE

- 22inch Touch Screen Display

- Mobile Computer Console

- - Move Display Close to Correction Zones

- Windows 10 IOT Operating System

- Custom End Drive and Adapter System

- Linear Rail Column Traverse

- - Effortless Positioning of Long Workpieces

- Optional Safety Cages and Enclosures

- Integrated Straightening Instrumentation

- Modular Base Structure

- - Extendable to Accommodate Long Augers

PROCESS OF BALANCING AN AUGER

An unbalanced auger can lead to reduced performance, premature wear, and potential damage to equipment or structures. Dynamic balancing is important for augers, as static balancing may not adequately address the dynamic unbalance that can occur. Dynamic unbalance occurs when the mass of an auger is unevenly distributed around its axis of rotation, causing vibration and stress on the equipment during operation.

Balancing augers is a multifaceted process that goes beyond just adjusting weight distributions. One of the primary concerns is the straightness of the auger. The welding of flightings to the central shaft at different points can introduce stresses that cause the auger to warp or bend, leading to the undesirable effect of 'whipping' when it rotates. This whipping not only produces significant unbalance due to uneven weight distribution but also poses operational challenges and safety concerns.

Before addressing the distribution of flighting mass, it's vital first to ensure the auger's straightness. This is achieved by applying heat to specific areas of the shaft, allowing the metal to relax and return to its original, straight form - a process known as stress relief. With ProBal's auger balancing machines, equipped with linear rails, this process becomes more precise. Our machines come with an integrated indicator system that smoothly traverses along the base, efficiently measuring the straightness of the shaft. This combination of straightening and subsequent precise balancing ensures that augers operate at peak efficiency and safety.

While dual-flighting augers tend to be more naturally balanced due to their symmetrical design, single-flighting augers present a unique challenge. The absence of offset mass in single-flighting augers means that they aren't inherently balanced. Therefore, significant weight must be added toward each end to counteract this missing mass and achieve a harmonious balance. This process ensures that the auger operates efficiently, reduces wear and tear, and optimizes safety during use.

Balancing augers is a multifaceted process that goes beyond just adjusting weight distributions. One of the primary concerns is the straightness of the auger. The welding of flightings to the central shaft at different points can introduce stresses that cause the auger to warp or bend, leading to the undesirable effect of 'whipping' when it rotates. This whipping not only produces significant unbalance due to uneven weight distribution but also poses operational challenges and safety concerns.

Before addressing the distribution of flighting mass, it's vital first to ensure the auger's straightness. This is achieved by applying heat to specific areas of the shaft, allowing the metal to relax and return to its original, straight form - a process known as stress relief. With ProBal's auger balancing machines, equipped with linear rails, this process becomes more precise. Our machines come with an integrated indicator system that smoothly traverses along the base, efficiently measuring the straightness of the shaft. This combination of straightening and subsequent precise balancing ensures that augers operate at peak efficiency and safety.

While dual-flighting augers tend to be more naturally balanced due to their symmetrical design, single-flighting augers present a unique challenge. The absence of offset mass in single-flighting augers means that they aren't inherently balanced. Therefore, significant weight must be added toward each end to counteract this missing mass and achieve a harmonious balance. This process ensures that the auger operates efficiently, reduces wear and tear, and optimizes safety during use.

MODULAR LINEAR GUIDEWAY BASE DESIGN

Recognizing the importance of precision and efficiency, ProBal's modular base design doesn't stop at adaptability. Each base is seamlessly integrated with linear rails, ensuring that the support columns can be positioned smoothly and effortlessly. This feature underscores our commitment to detail and operational ease, providing our users with a flawless experience every time. Whether you're handling a short auger or one that extends beyond 40 feet, our machine's design guarantees meticulousness and convenience in equal measure.

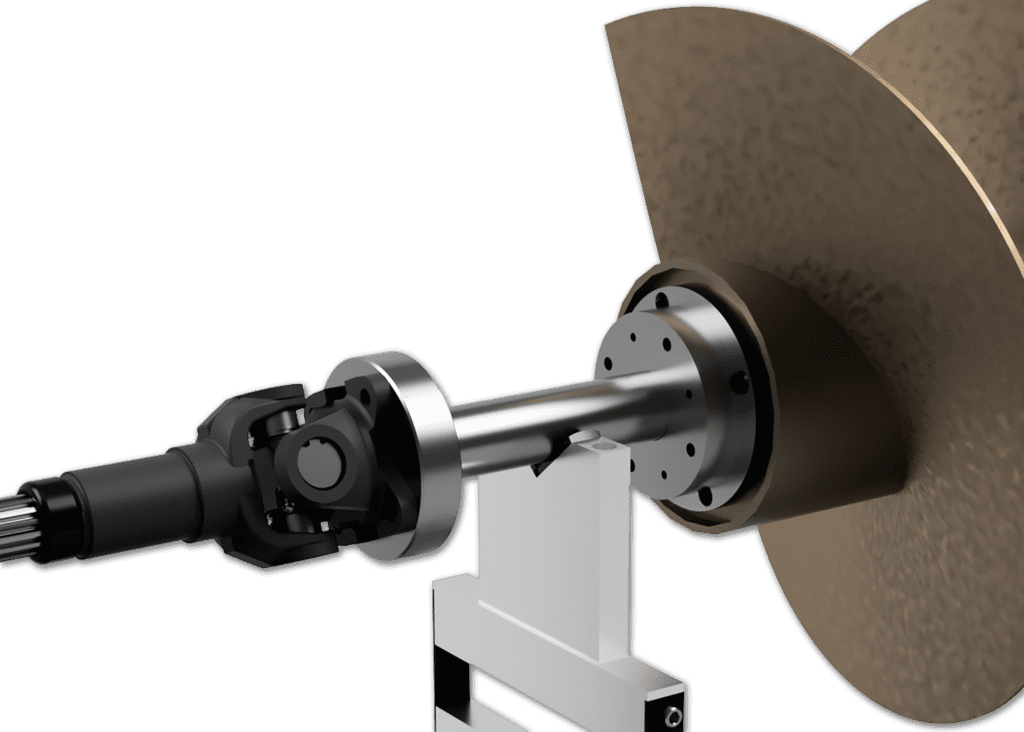

CUSTOM ADAPTER DESIGN PROVIDED

We offer comprehensive solutions when it comes to drive adapters, suitable for both end drives and overhead drives. Our team can expertly design and manufacture these adapters, ensuring they're ready for immediate use upon machine delivery. Alternatively, for those who prefer a hands-on approach, we provide detailed guidelines enabling customers to create their own adapters. It's all about flexibility and you can choose a path that best aligns with your operational needs, be it a full-service provision, guidance for DIY, or a tailored combination of both.

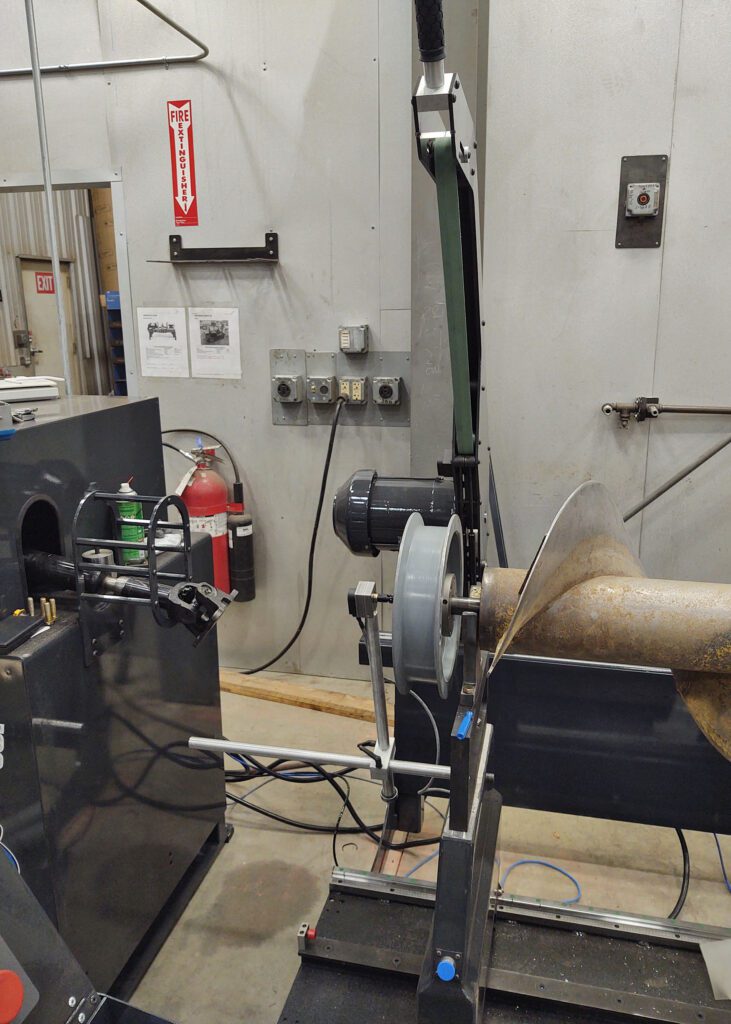

DUAL DRIVE SYSTEMS AVAILABLE

Auger manufacturing and remanufacturing introduce a wide array of designs, each demanding a unique approach. Recognizing this diversity, ProBal offers a versatile solution tailored to meet varying demands. Our machines come equipped with two distinct drive types: overhead and end-drive, ensuring you have the flexibility needed to cater to a wide spectrum of auger designs.

While end-drives boast remarkable stability, they necessitate specific adapters for seamlessly connecting the driveshaft to the auger. This can be optimal for certain setups, ensuring a snug and secure fit. In contrast, the overhead drive employs a belt that descends and engages with a drive hub. This hub must be affixed to the auger itself, facilitating a different mode of operation that might be more suitable in certain situations. With ProBal, adaptability is at your fingertips, ensuring you're always prepared for any auger design that comes your way.

While end-drives boast remarkable stability, they necessitate specific adapters for seamlessly connecting the driveshaft to the auger. This can be optimal for certain setups, ensuring a snug and secure fit. In contrast, the overhead drive employs a belt that descends and engages with a drive hub. This hub must be affixed to the auger itself, facilitating a different mode of operation that might be more suitable in certain situations. With ProBal, adaptability is at your fingertips, ensuring you're always prepared for any auger design that comes your way.

GET IN TOUCH

Do you have a question you would like to ask us?