Selling Solutions Not Just Machines | More than just a one-size-fits-all machine. We make sure that your machine is tailored to fit your balancing needs. We can custom build your balancing machine to accommodate your specific parts and safety requirements. |

FULLY CUSTOMIZED BALANCING MACHINES

Whether one of our standard models or a custom build suited specifically to your needs, we'll get you squared away. We guarantee you will be more productive, efficient and stress free with our easy to use software.

ON-SITE PERSONALIZED TRAINING

Each machine gets our personal touch. We'll visit your shop, ensuring the machine is set up correctly, and provide comprehensive training so you can operate it like a pro. Instead of simply demonstrating its functions kaskustoto login, we'll confirm that you're proficient and can independently handle the machine, as if we weren't present. Our aim? We won't leave until you're making money with it.

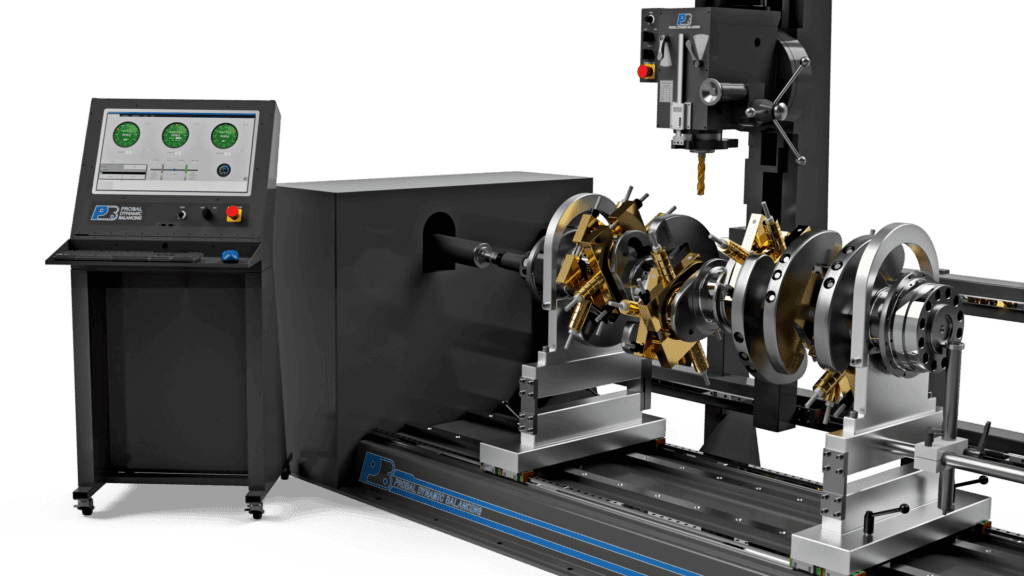

At ProBal, we offer versatile and customized Horizontal Balancing machines that are adaptable to a variety of applications. These machines can handle diverse parts, ranging from turbines to rotors, and are tailored to your unique requirements. Our horizontal machines boast a modular design with composite-filled steel bases for extra stability kaskustoto, and different trunnion types to accommodate any part.

Our machines are built with three distinct drive systems: overhead, wrap-around, and direct drive, enhancing their adaptability. Furthermore, our software, built on a Windows embedded operating system, is touchscreen-friendly, kaskustoto login simplifying user management and control.

One key feature of our machines is the use of piezo-electric sensors for real-time unbalance readings. Coupled with live encoder feedback, we ensure the balancing process is seamless by displaying RPM and correction location.

Each of our horizontal machines includes a proving rotor, facilitating an easy verification of machine accuracy and calibration. Backed by our rich experience in dynamic balancing systems situs toto, we provide first-class training and service, ensuring a smooth start and a tailored solution for your balancing needs.

Our machines are built with three distinct drive systems: overhead, wrap-around, and direct drive, enhancing their adaptability. Furthermore, our software, built on a Windows embedded operating system, is touchscreen-friendly, kaskustoto login simplifying user management and control.

One key feature of our machines is the use of piezo-electric sensors for real-time unbalance readings. Coupled with live encoder feedback, we ensure the balancing process is seamless by displaying RPM and correction location.

Each of our horizontal machines includes a proving rotor, facilitating an easy verification of machine accuracy and calibration. Backed by our rich experience in dynamic balancing systems situs toto, we provide first-class training and service, ensuring a smooth start and a tailored solution for your balancing needs.

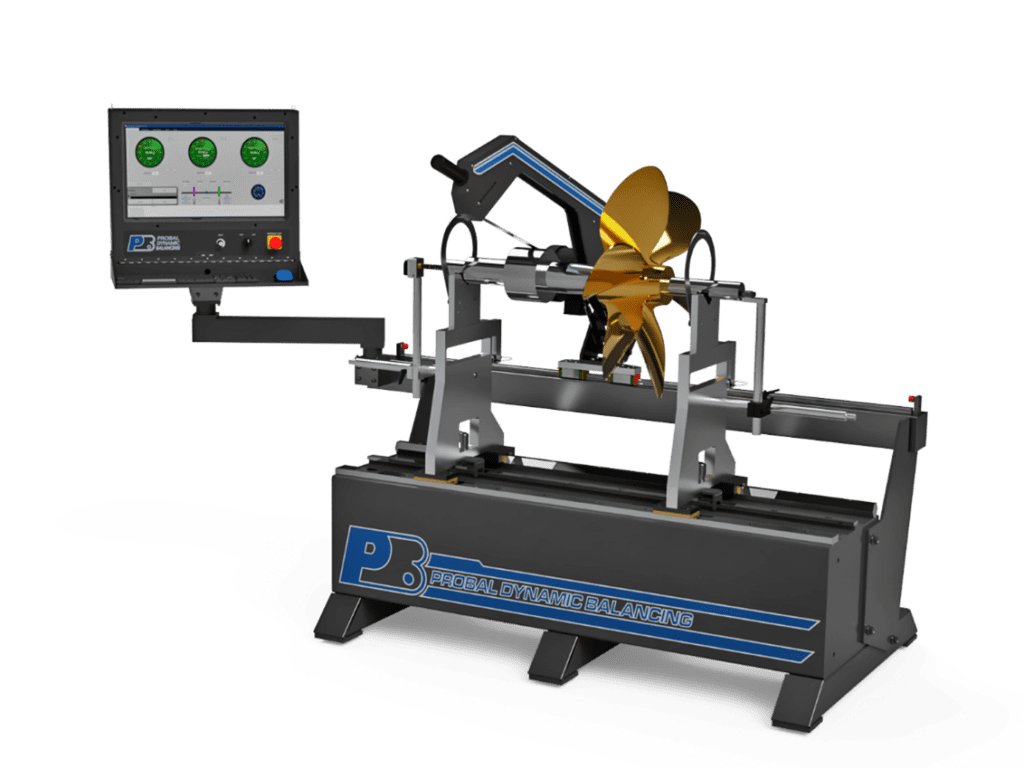

At ProBal, we offer customized Vertical Balancing machines tailored to meet your specific requirements. Our machines come equipped with multiple measurement modes, a custom spindle design, fast measurement cycles, and the ability to integrate a drill press. We utilize a user-friendly Windows 10 Embedded system on a 22' touchscreen computer and provide various automation solutions.

Our vertical balancers are designed to efficiently balance parts like flywheels, pulleys, gears, fans, and clutch plates, delivering rapid, high-definition single or dual plane data. To ensure consistent reliability and accuracy, we incorporate hard-bearing spring assemblies and permanent calibration into our machines. Moreover, these machines can be upgraded for automatic corrections with drill press attachments or welding arms.

We understand the value of space in compact workshops, hence, our vertical machines are designed to occupy less floor space. Additionally, they seamlessly integrate with correction methods for a streamlined balancing process. To ensure our solution meets your specific needs, we work closely with you, providing real-time remote feedback and 3D part viewing before shipping.

Our vertical balancers are designed to efficiently balance parts like flywheels, pulleys, gears, fans, and clutch plates, delivering rapid, high-definition single or dual plane data. To ensure consistent reliability and accuracy, we incorporate hard-bearing spring assemblies and permanent calibration into our machines. Moreover, these machines can be upgraded for automatic corrections with drill press attachments or welding arms.

We understand the value of space in compact workshops, hence, our vertical machines are designed to occupy less floor space. Additionally, they seamlessly integrate with correction methods for a streamlined balancing process. To ensure our solution meets your specific needs, we work closely with you, providing real-time remote feedback and 3D part viewing before shipping.

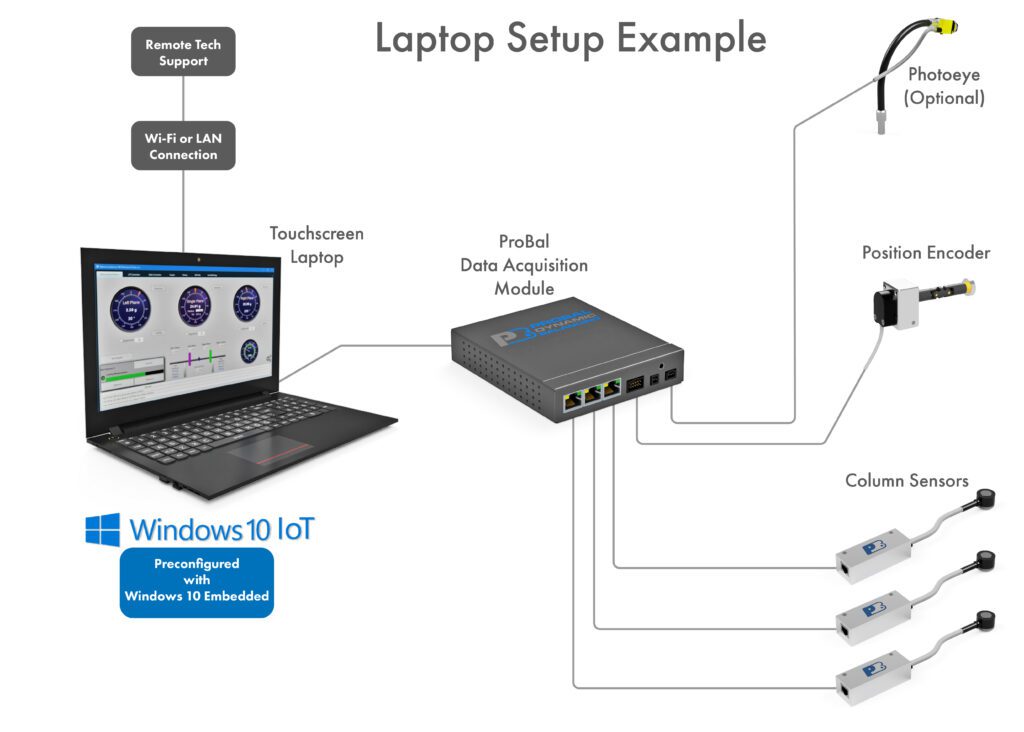

At ProBal, we breathe new life into your aging dynamic balancing machines by offering electronics upgrades. If your system becomes outdated or unreliable, we provide a cost-effective solution that brings your machine up to date with the latest technology, without the need to invest in a new one. We offer upgrades and retrofits for numerous brands, adapting to any hard-bearing balancing machine and even offering conversions for soft-bearing machines.

Our retrofit involves replacing sensors, encoders, computer, wiring, and motor drives with new components. This process makes your machines more accurate and sensitive than worn-out or outdated components. This cost-effective solution eliminates rigging and transport costs and reduces downtime compared to getting a new machine.

Our upgrades feature multiple control solutions, including a laptop, all-in-one computer, or a mobile console. Our systems offer fast sample times, Windows 10 Embedded Operating System, and on-site installation and training. The core electronics come with a lifetime warranty, while sensors and computer have a one-year parts and labor warranty.

Moreover, we commit to lifetime software updates, ensuring your machines remain current and accurate. We support a wide range of balancing applications, and bringing your balancing machines up to current industry standards - even those from the 1950s!

Our retrofit involves replacing sensors, encoders, computer, wiring, and motor drives with new components. This process makes your machines more accurate and sensitive than worn-out or outdated components. This cost-effective solution eliminates rigging and transport costs and reduces downtime compared to getting a new machine.

Our upgrades feature multiple control solutions, including a laptop, all-in-one computer, or a mobile console. Our systems offer fast sample times, Windows 10 Embedded Operating System, and on-site installation and training. The core electronics come with a lifetime warranty, while sensors and computer have a one-year parts and labor warranty.

Moreover, we commit to lifetime software updates, ensuring your machines remain current and accurate. We support a wide range of balancing applications, and bringing your balancing machines up to current industry standards - even those from the 1950s!

GET A QUOTE!

Start your balancing solution quote with one of our sales engineers.

1

Speak with one of our highly-trained sales engineers while we evaluate your needs to deliver the best possible solution for your application or situation.2

We can provide a turnkey package so that you are up and running quickly. Whether you choose to upgrade your existing machine or purchase a new complete package, we’ll make sure your purchase is stress-free.3

You can relax knowing that your ProBal control is not only one of the best balancing systems available, but you will always have world-class support just a phone call away.30 YEARS OF SATISFIED CUSTOMERS

Without our loyal customers, our work would be lackluster. Check out what our past and current clients have to say about working with ProBal Dynamic Balancing.

Our Story Speaks For Itself

ProBal was formed in 1990 to purchase the former Stewart Warner Balancing Division which was founded in 1950. We continue to service and retrofit these machines with the same high-quality standards we've held for 70 years.

DON'T SETTLE FOR LESS

ProBal offers superior balancing solutions that increase productivity, safety, and lifespan of your rotating machinery. Contact us today.

PHONE

(940) 668-1126

TEXT US

(650) 910-7240

GET IN TOUCH

Do you have a question you would like to ask us?