Edge Mill Mount System

A Smarter Balancing Solution That Fits Your Budget and Your Shop.

Space-Saving Balancing Machine

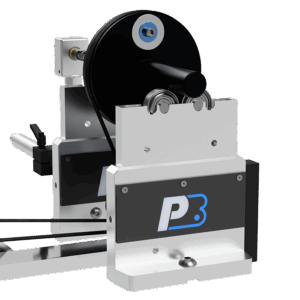

The Edge Mill Mount System delivers precision balancing in a compact, affordable kit.

Mount it to your mill or standalone base and enjoy fast setup, versatile correction options,

and reliable performance.

Mount it to your mill or standalone base and enjoy fast setup, versatile correction options,

and reliable performance.

Overview: A Compact, Affordable Dynamic Balancing Solution

The Edge Mill Mount Balancing System offers an efficient, cost-effective approach to dynamic balancing for automotive and industrial applications. By mounting directly to a Bridgeport-style milling machine, the Edge Balancing system eliminates the need for a dedicated standalone machine, saving valuable floor space and significantly reducing equipment investment.

Designed for flexibility, the Edge Mill Mount system features a powerful, compact, lightweight 12-pound drive motor assembly that makes setup and teardown quick and effortless. Its small footprint and modular design allow operators to easily mount or remove the system as needed, minimizing downtime and maximizing shop versatility. Kits are typically available to ship within just a few weeks, giving shops a fast, affordable path to add balancing capability without the long waits associated with traditional machines.

Designed for flexibility, the Edge Mill Mount system features a powerful, compact, lightweight 12-pound drive motor assembly that makes setup and teardown quick and effortless. Its small footprint and modular design allow operators to easily mount or remove the system as needed, minimizing downtime and maximizing shop versatility. Kits are typically available to ship within just a few weeks, giving shops a fast, affordable path to add balancing capability without the long waits associated with traditional machines.

ProBal’s Mill Mount system provides multiple configuration paths to meet your shop’s balancing needs, with control options including Windows IoT laptops, integrated all-in-one PCs, or ruggedized enclosures. For operations without an available mill, the Edge DBS platform provides a complete standalone solution with integrated correction drilling capabilities.

By combining precision hard-bearing balancing, compact design, fast deployment, and a lower total cost of ownership, the Edge Mill Mount Dynamic Balancing System gives shops a smarter way to expand their balancing capabilities without overextending budgets or floor plans.

By combining precision hard-bearing balancing, compact design, fast deployment, and a lower total cost of ownership, the Edge Mill Mount Dynamic Balancing System gives shops a smarter way to expand their balancing capabilities without overextending budgets or floor plans.

Edge Mill Mount System Features

| Bridgeport-Compatible Design | Mounts directly to Bridgeport-style milling machines with no dedicated floor space required. |

| Compact Drive Motor | 12-pound, 1.3 HP brushless DC motor for fast setup and easy teardown by a single operator. |

| Minimal Footprint | Converts existing equipment into a dynamic balancer without the need for new machinery. |

| Quick Changeover | Modular design makes it easy to switch between balancing and machining tasks. |

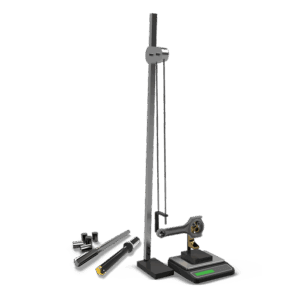

| Engine Shop Accessories | Supports optional tooling like bobweights, gram scales, and rod-weighing fixtures. |

| Flexible Computer Options | Choose a laptop, touchscreen PC, or rugged enclosure based on your workflow and shop environment. |

| Fast Lead Time | Standard kits can ship within a few weeks. |

| Portable & Versatile | Easy to store, transport, or share between stations in multi-bay engine shops. |

| Expandable to Dedicated Station | Upgrade to a permanent Edge DBS setup later. Same core system, no need to repurchase components. |

Mounting Options

Choose the configuration that best fits your shop’s workflow

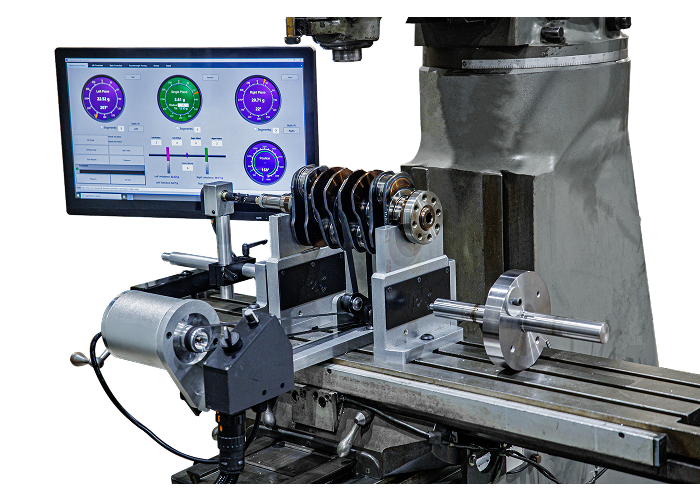

Mill-Mounted System

The Edge Mill Mount System installs directly onto a standard Bridgeport-style milling machine, turning existing equipment into a fully capable dynamic balncing station. This setup saves valuable floor space and allows quick changeover between machining and balancing tasks. The lightweight drive assembly makes it easy to mount or remove the system as needed, giving shops maximum flexibility without the need for a dedicated footprint.

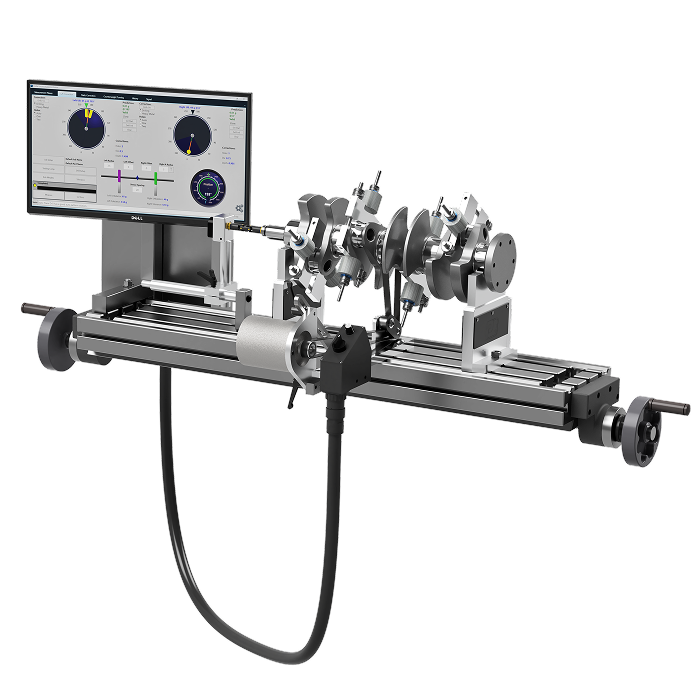

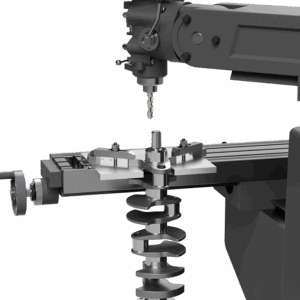

Edge DBS Standalone System

For shops without a milling machine, or those who prefer a permanent balancing station, the Edge DBS offers a complete, self-contained solution. Built on a rigid custom base with integrated linear rail slides for correction drilling, the Edge DBS delivers the same balancing performance as the mill-mounted version. It’s a compact, space-efficient station ideal for crankshaft balancing and engine assembly work, that won’t tie up your mill.

Drive System

At the core of the Edge Mill Mount platform is a compact, 12-pound brushless DC motor delivering 1.3 horsepower of clean, controllable torque. Unlike bulky motors found on traditional balancing machines, this lightweight drive makes setup and teardown fast and manageable, even for a single operator. The motor’s compact size allows easy mounting on a mill table or standalone base without compromising power, making it an ideal fit for both performance and remanufacturing engine shops.

Customization & Applications

While the Edge system is widely used in engine balancing, it’s also adaptable for rotors, impellers, fans, and other rotating components. We customize fixturing, mounting setups, and control configurations to match your parts and processes whether you're balancing a crankshaft, a blower wheel, or something entirely unique. Every system is built with flexibility in mind to support production, remanufacturing, and prototyping across industries.

Your Path to a Balanced Solution

Designed to get you balancing fast with no guesswork.

Define Your Needs

We start with a conversation. What parts are you balancing and how often? From crankshafts to custom rotors, we’ll identify the right configuration for your work.

Build Your System

Based on your requirements, we configure your Edge kit with the right mounting, motor, control, and accessory options. Everything is prepped for your workflow and assembled in-house for fast delivery.

Ship, Train, and Support

Your system ships in just a few weeks. We offer remote and on-site training as needed, plus lifetime support to keep you balancing with confidence.

DON'T SETTLE FOR LESS

ProBal offers superior balancing solutions that increase productivity, safety, and lifespan of your rotating machinery. Contact us today.

GET IN TOUCH

Do you have a question you would like to ask us?