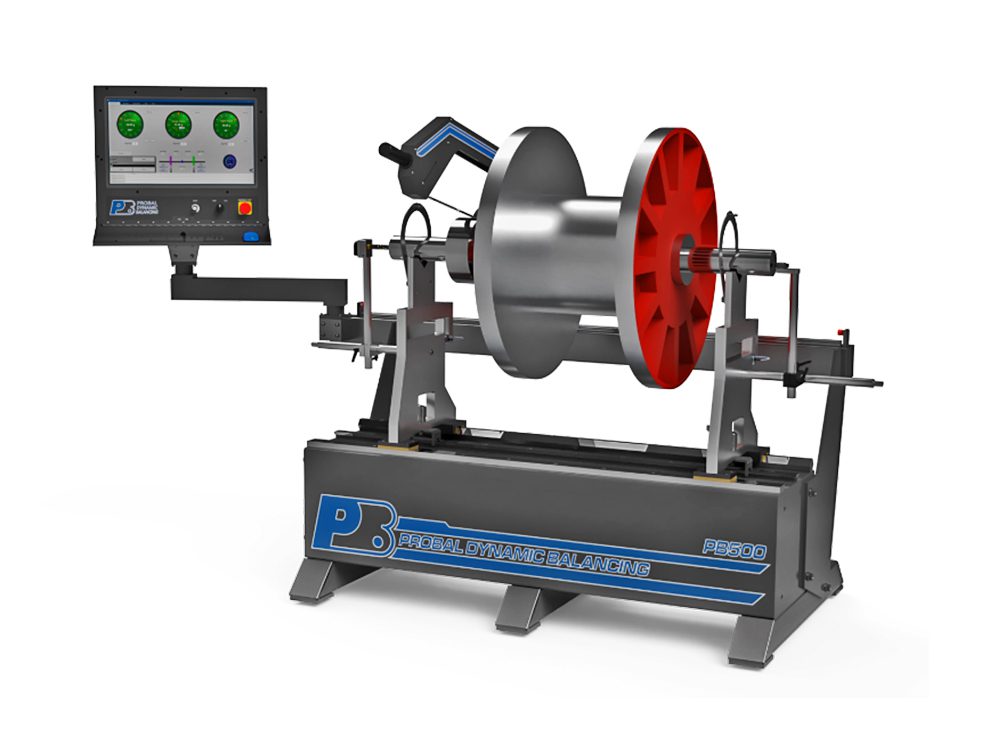

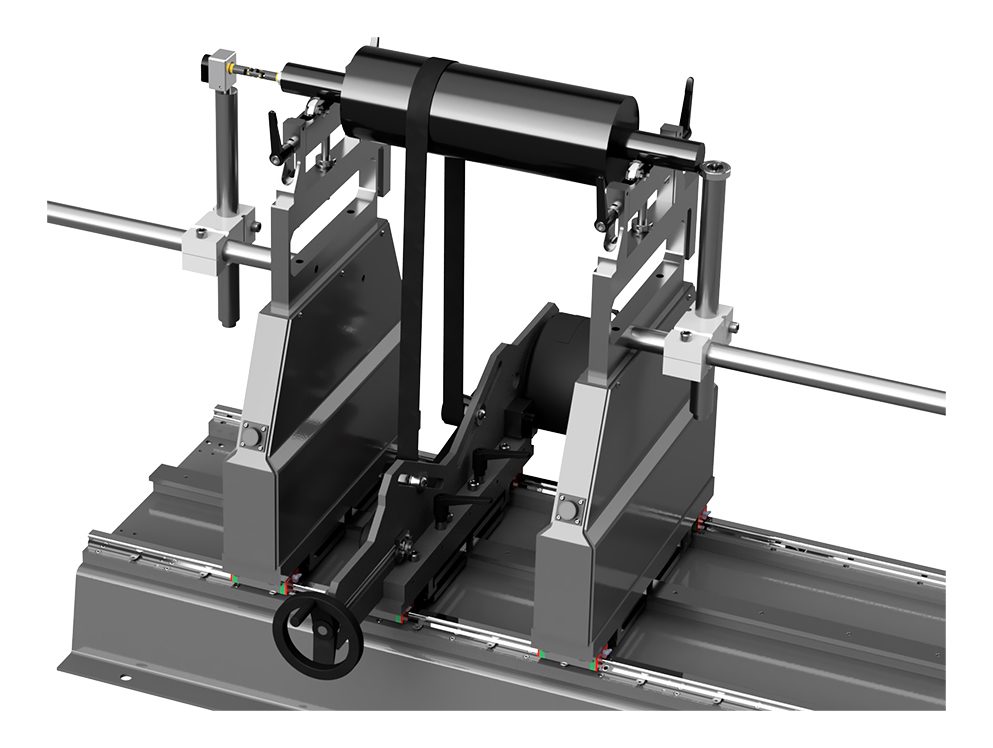

ProBal horizontal balancing machines are the most commonly used configuration of balancing machines to accurately measure and correct a myriad of parts. From turbines to U-joints, propellers to augers, and centrifugal fans to rotors, we have model sizes to fit nearly any application.

While universal horizontal balancing machines may be common, we like to build our balancers with a customized drive system, mount and correction system.

Take a look at our lineup and list of industry applications; or contact us to customize a balancing solution to fit your needs.

While universal horizontal balancing machines may be common, we like to build our balancers with a customized drive system, mount and correction system.

Take a look at our lineup and list of industry applications; or contact us to customize a balancing solution to fit your needs.

Applications

- Electric Motors

- Rotors

- Crankshafts

- Driveshafts

- Flywheels

- Turbochargers

- Centrifugal Fans

- Pumps

- Impellers

- Spindles

- Grain Augers

- Agricultural Parts

- Straw Choppers

- Grain Grinders

- Paper Mill Rollers

- Mud Pumps

- Cable Reels

- Propellers

OUR LINEUP

ProBal's horizontal balancing machines offer optimized balancing solutions for diverse component weights and industries.

MACHINES FOR ALL TYPES OF PARTS

Let us help you choose the right balancing machine.

Special Features

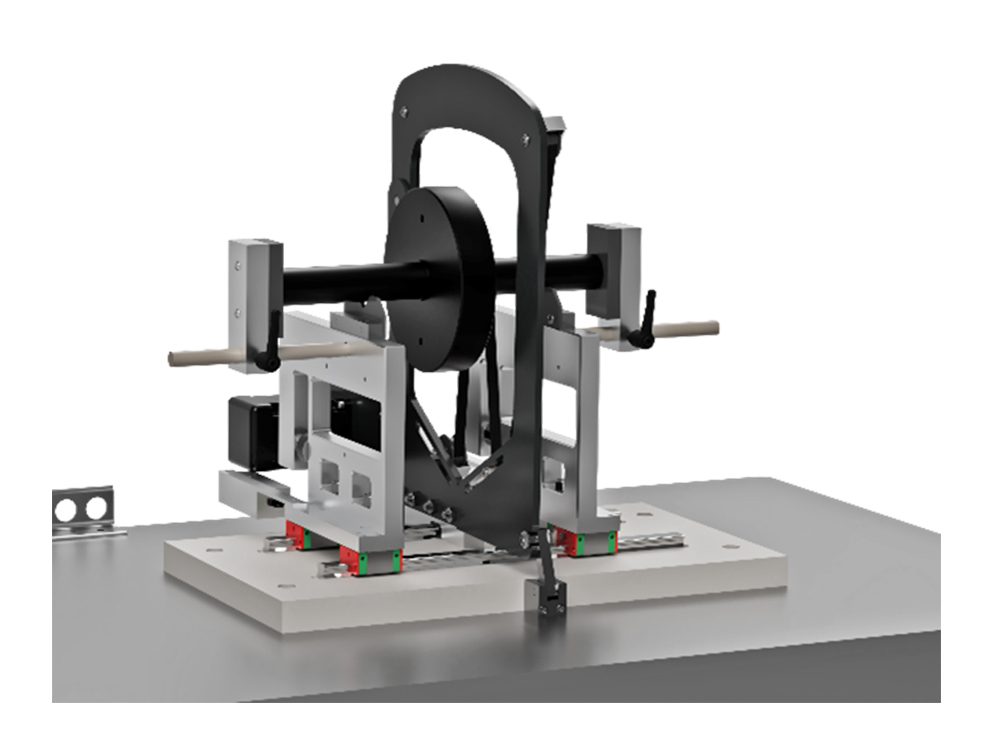

- Composite-filled steel bases for extra stability

- Linear bearing rail system for columns

- Variety of trunnion types to suit any part

- V-blocks

- Roller bearings

- Pillow blocks

- Modular design, allowing length extension

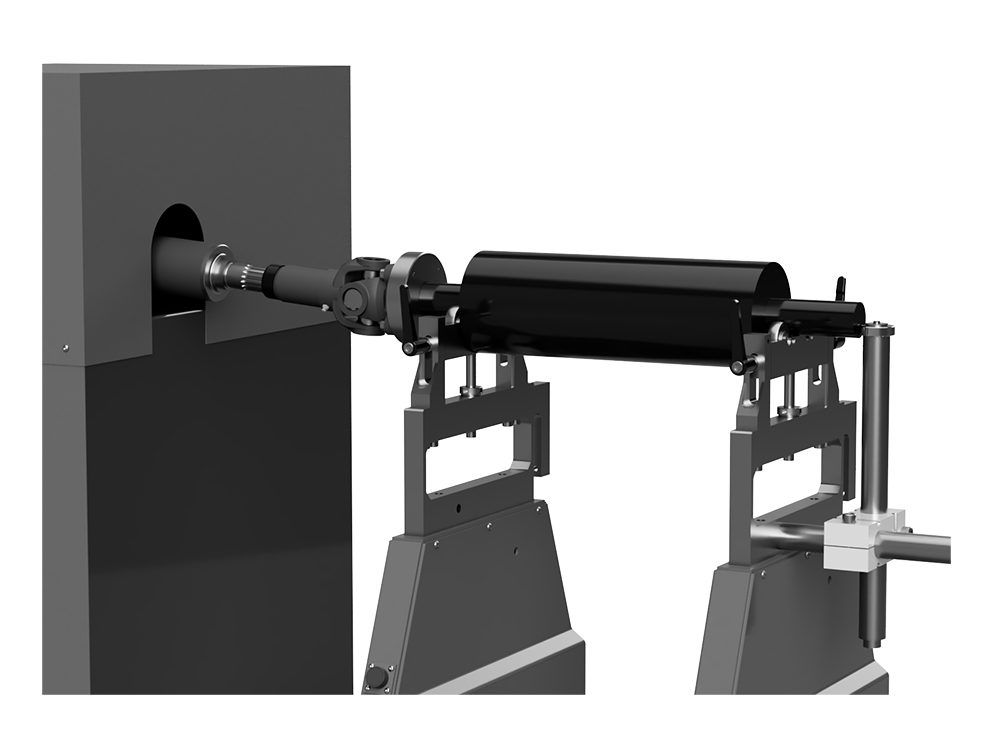

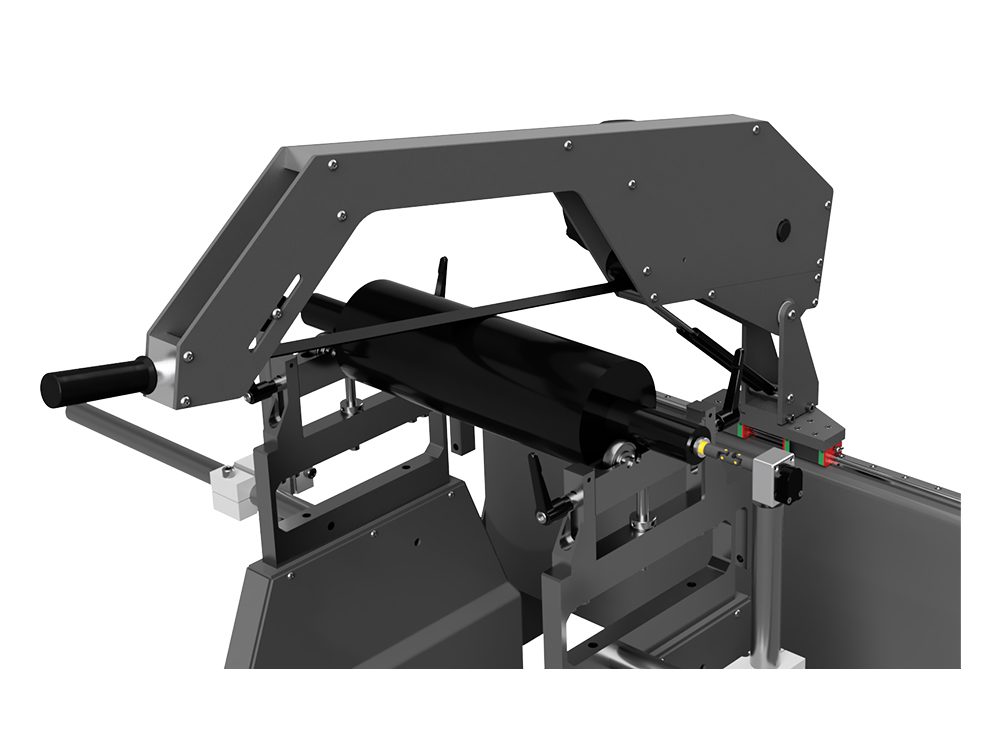

- 3 different drive types

- Overhead drive

- Wrap-around drive

- Direct drive

- Customized balancing solution specifically tailored to your part

- Simple to use touchscreen friendly balancing software

- First class training and service

Overview

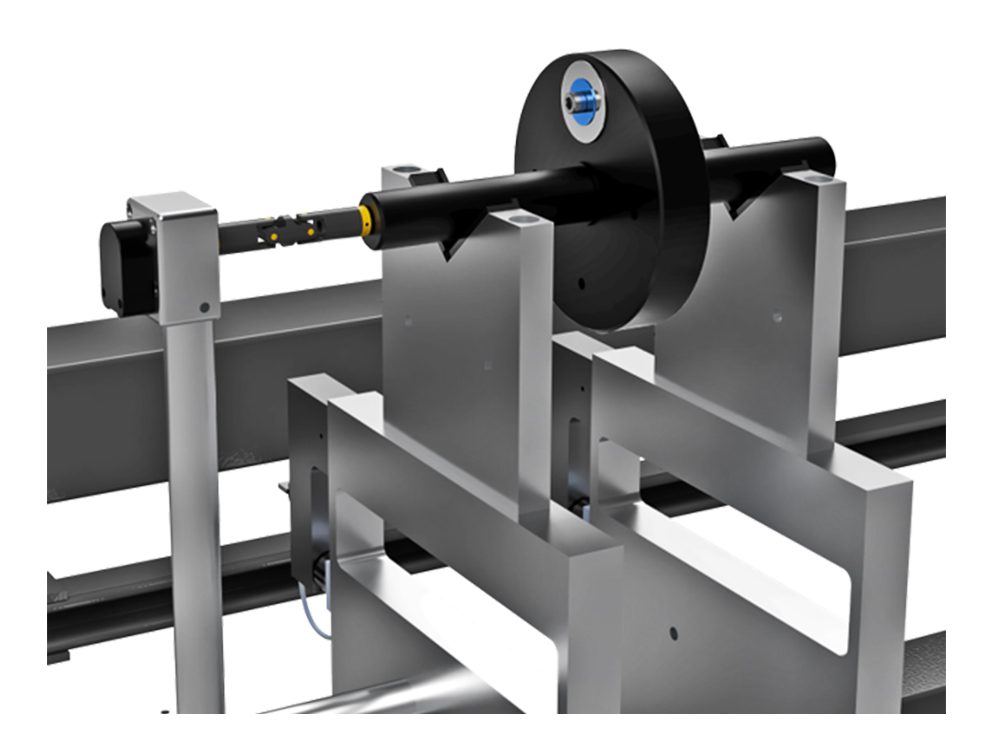

ProBal offers a wide range of horizontal balancing machines. Most balancing machines in the industry are horizontal, or cradle, type machines. The rotor or rotating assembly lies with its axis of rotation parallel to the floor. These are the most universal machines in the industry and can accommodate a wide range of parts and can be used for both single plane and multi plane balancing. For balancing, the rotating assembly is supported by vertical columns with roller bearings or V-blocks. These machines are used to balance very small rotors to very large.

Multiple Drive Solutions

Our machines utilize a modular design with extendable bases and multiple drive system options. We can quickly develop a comprehensive solution to balance virtually any type of rotating assembly. Through our proposal process we will review drawings and pictures of your parts and build a machine tailored to your specific process. In the case that custom mandrels or balancing arbors need to be designed and machined we can provide complete packages or design guidelines so that you can keep full control of your own development.

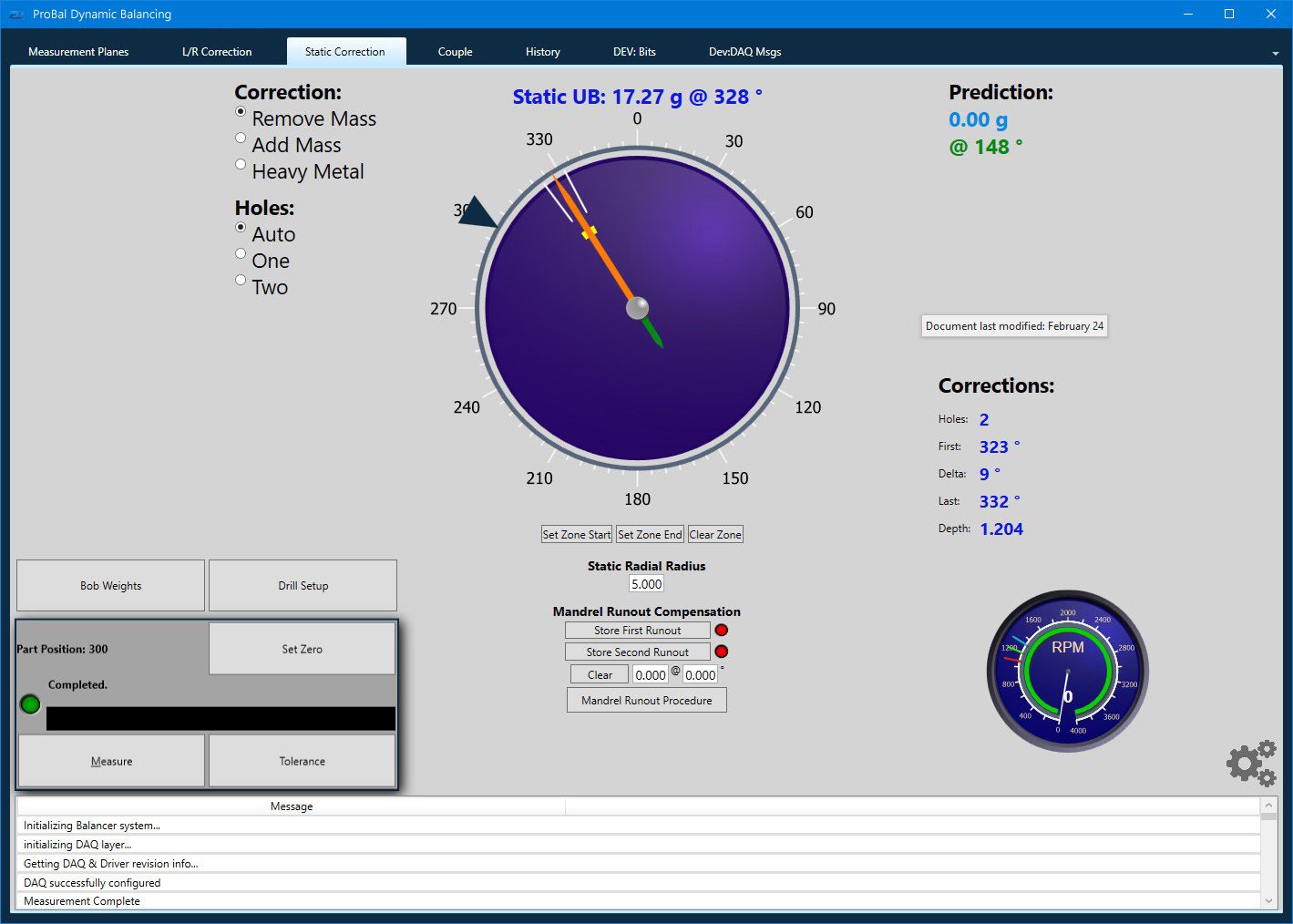

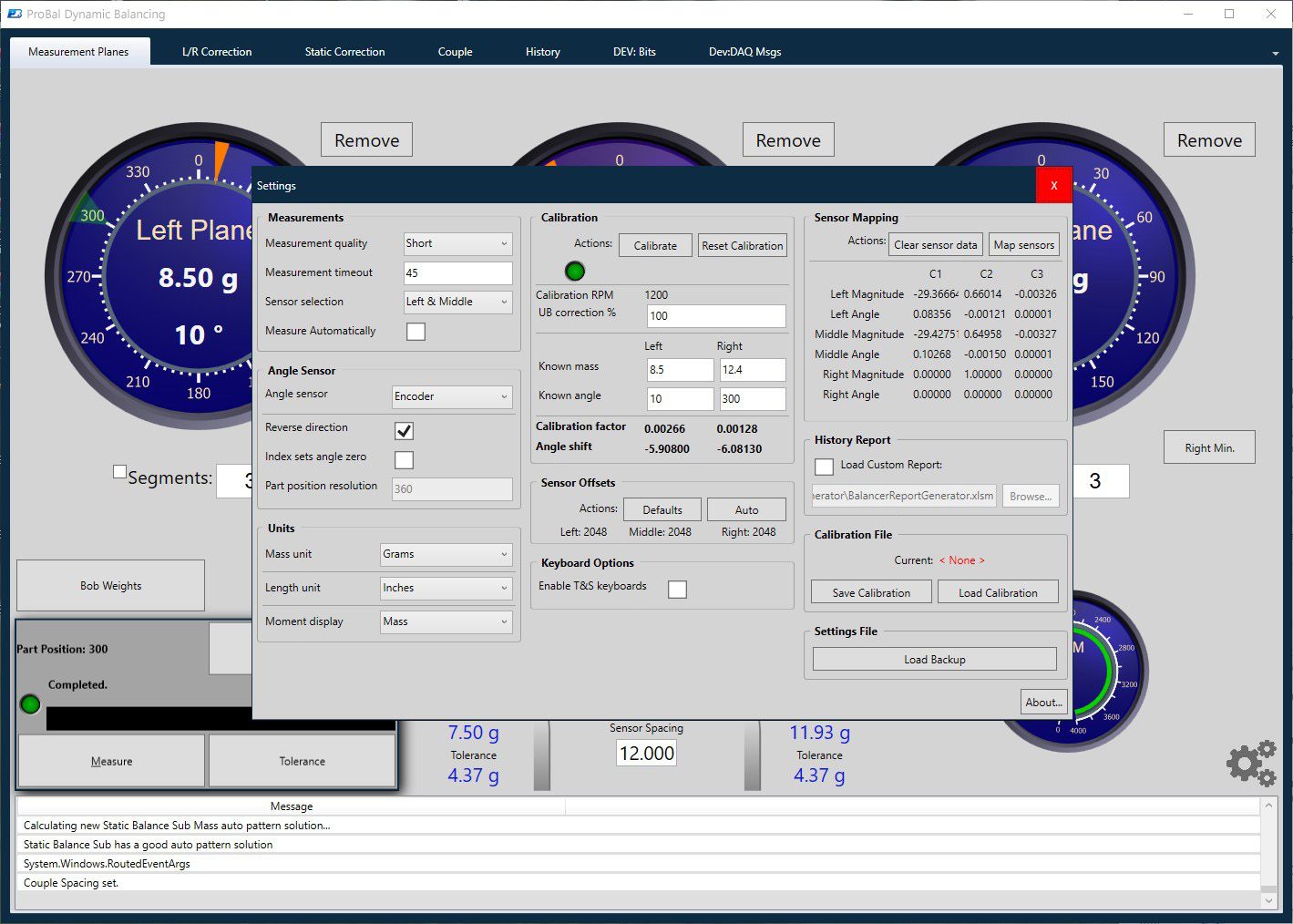

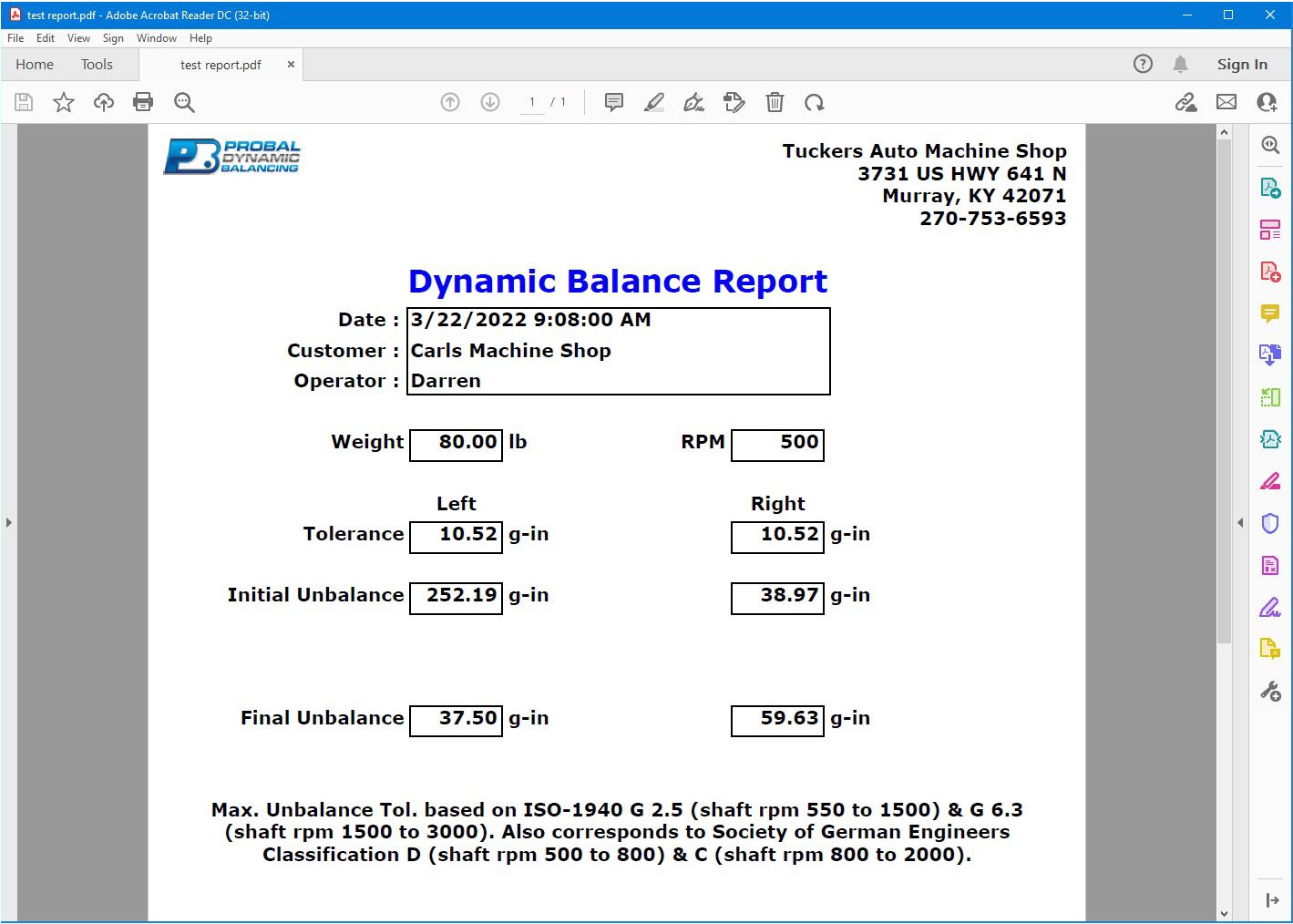

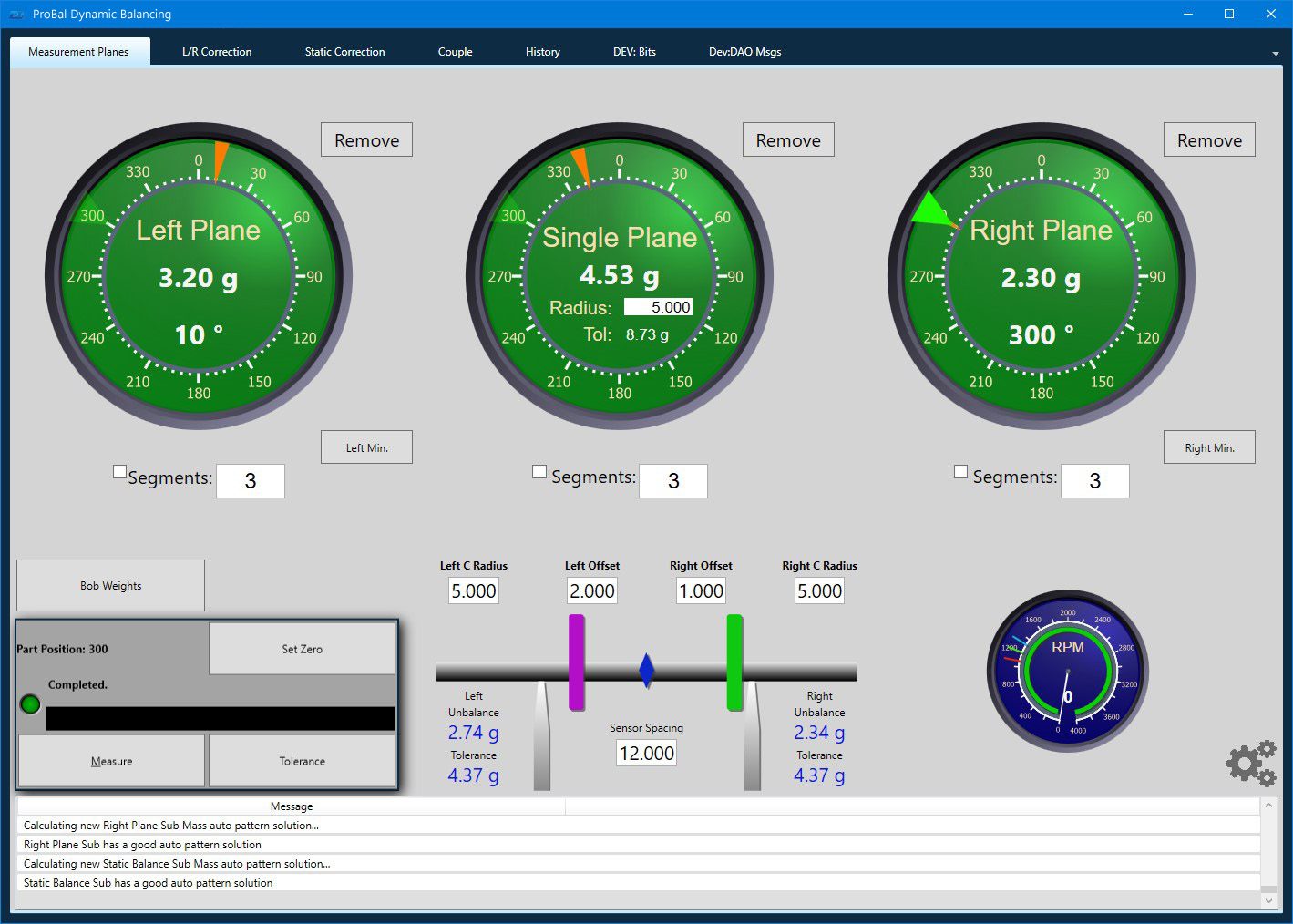

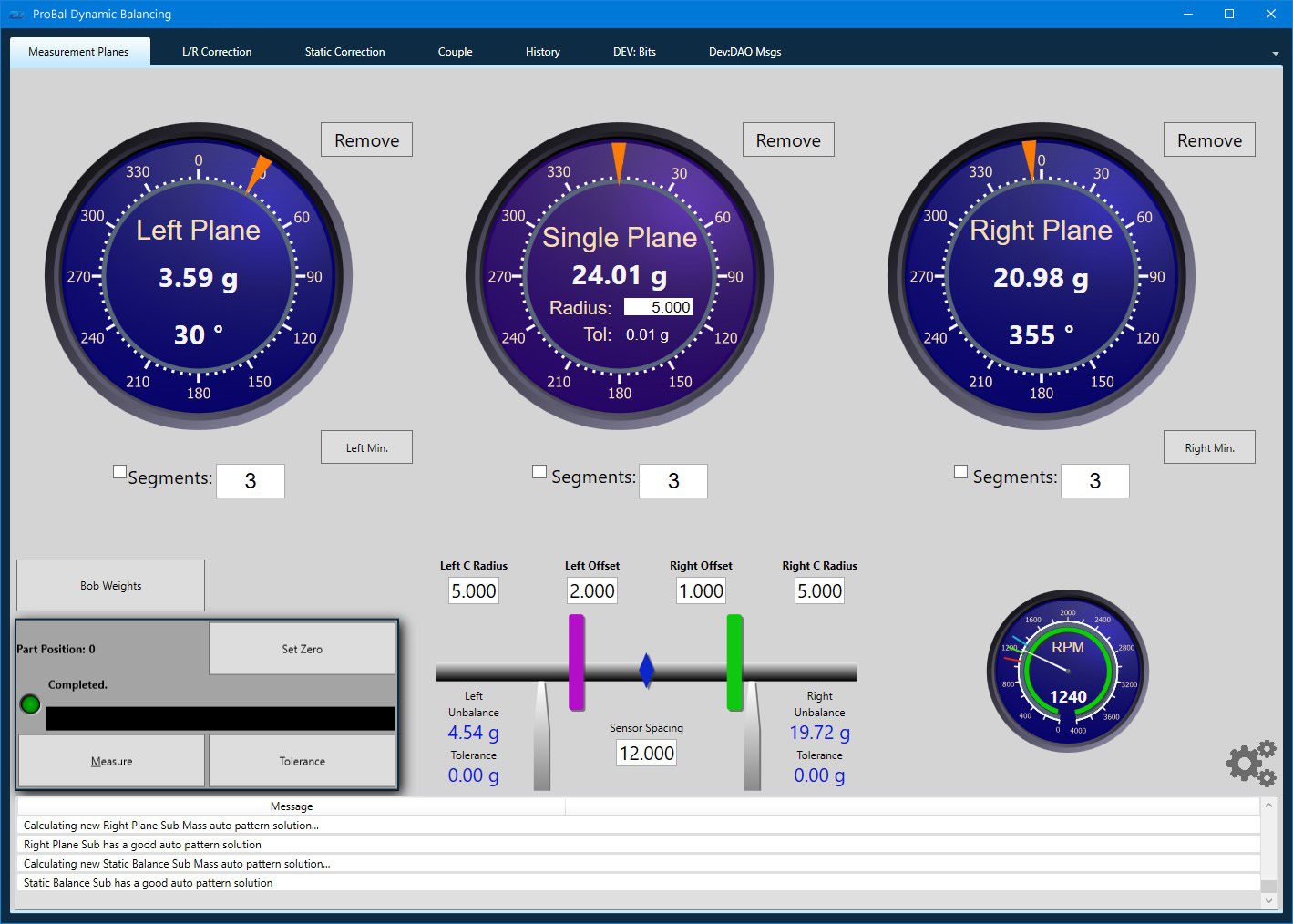

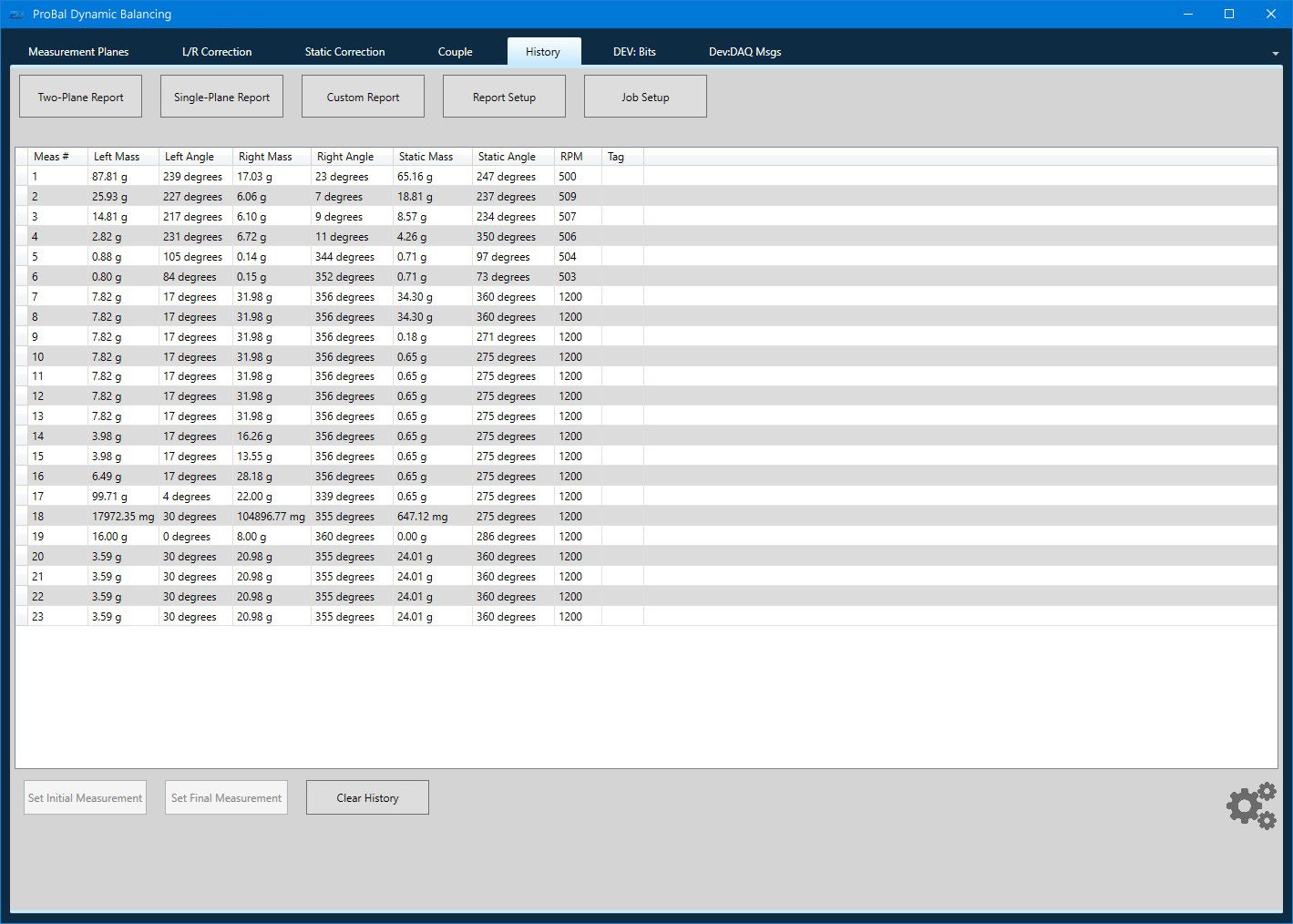

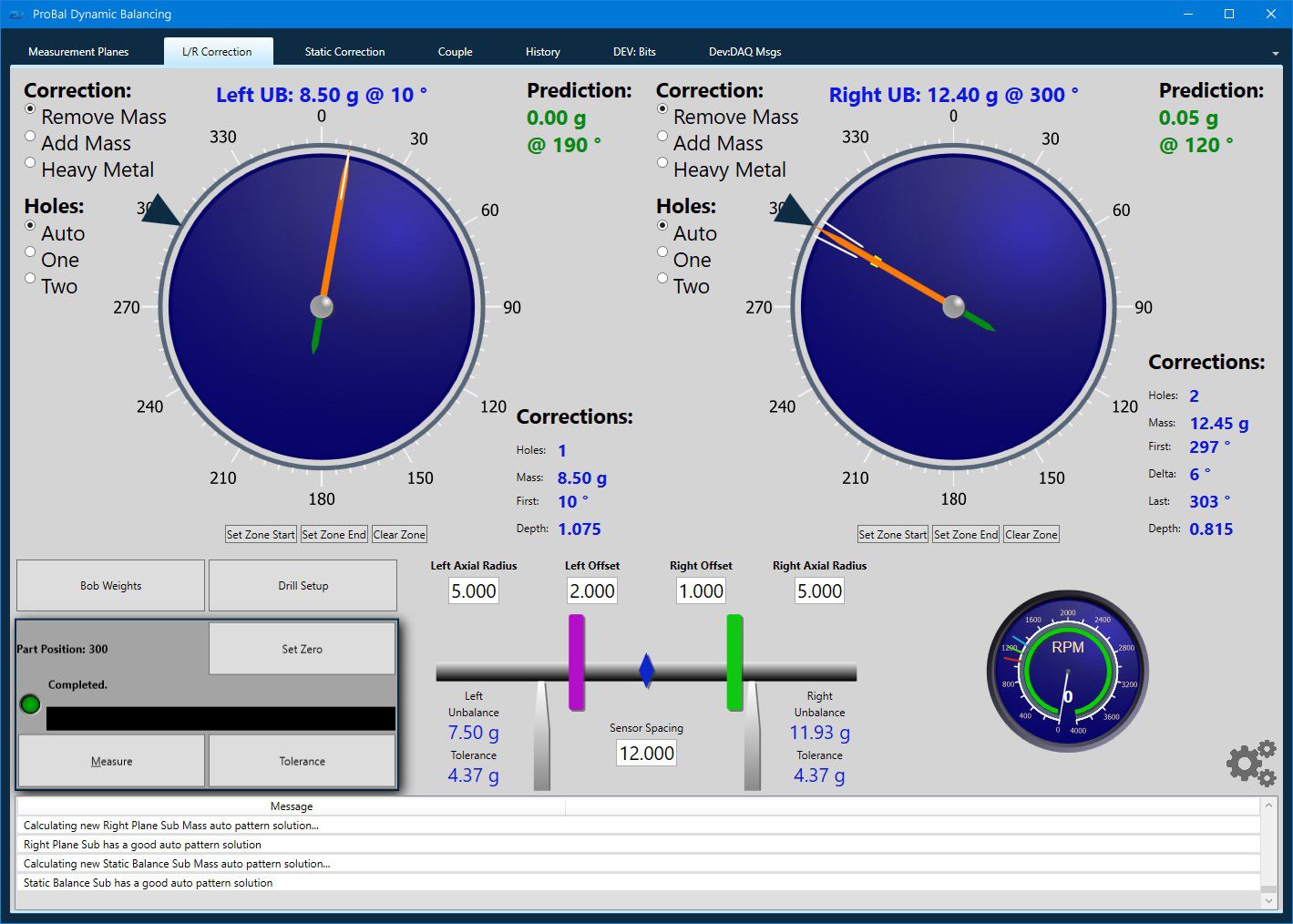

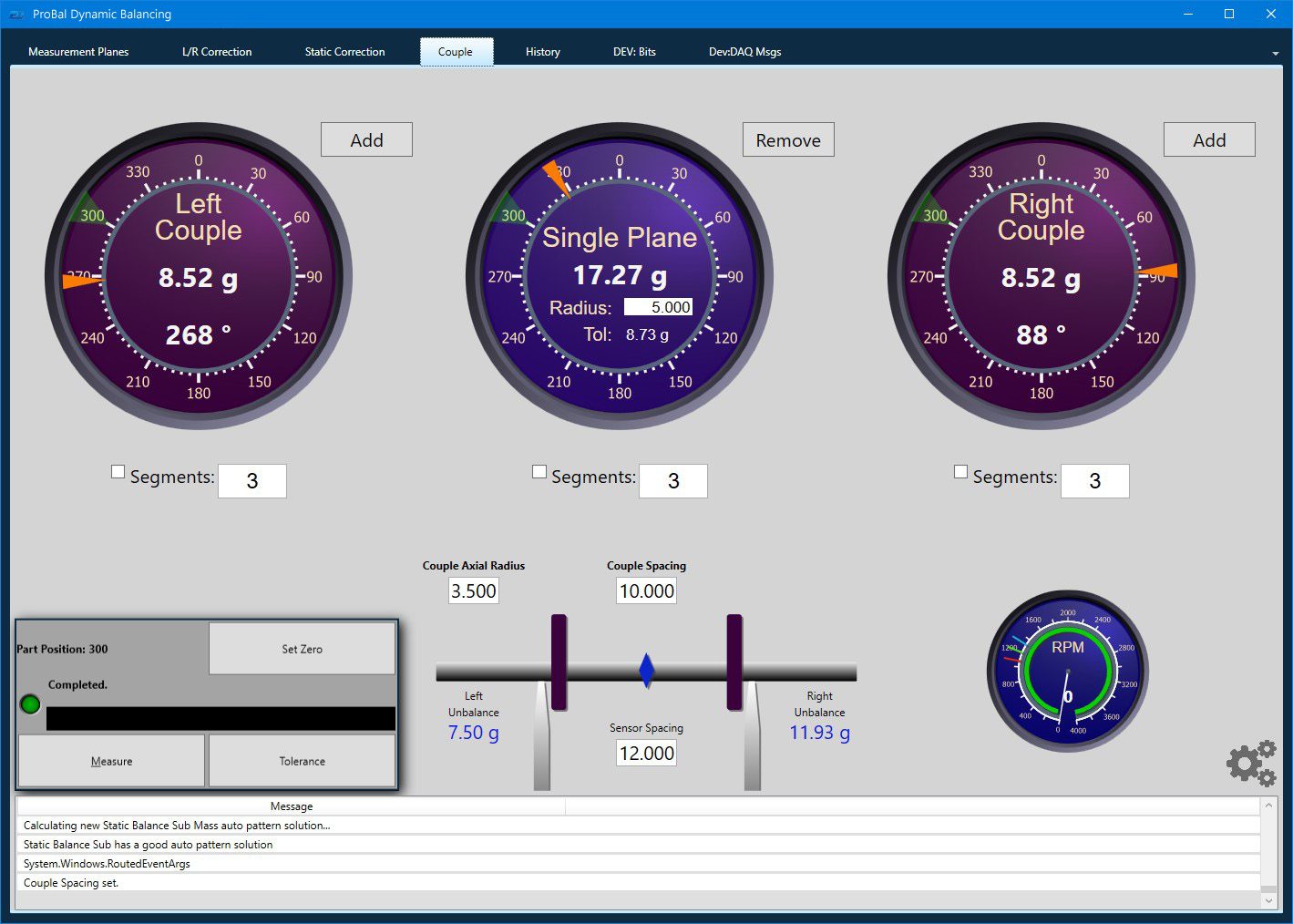

Highly Intuitive Software and Electronics

ProBal horizontal balancing machines utilize permanent calibration and modern electronics that ensures simple machine operation for your operators. Also, our balancing software is built on current Windows embedded operating system which gives your IT department full control over network access and user management.

Permanent Calibration

All ProBal horizontal balancing machines are supplied with an industry matched calibration tool, or proving rotor. This is to the benefit of both the customer and our machine support technicians to quickly discern performance issues over the life of the machine. In the event a questionable measurement result is encountered the operator has the ability to mount the proving rotor in the machine and quickly compare machine accuracy and calibration. It is our belief that modern hard-bearing horizontal balancing machines should include a verification tool in the same way a precision measurement instrument will have an accompanying standard to measure against.